For over 45 years, Alma has been at the forefront of nesting and CAD/CAM innovation, delivering cutting-edge 2D and 3D nesting software tailored to every cutting technology. We empower sheet metal manufacturers, machine builders, integrators and software developers with precision technologies that maximize material usage and improve workshops’ operations.

Nesting

developers

for 45

years

Game changer

Pioneers in Nesting Technology

Since 1979, Alma has led the way in nesting software. Originally developed by applied mathematics researchers to optimize material use in textile cutting, our innovation revolutionized the sheet metal industry. In 1983, the shipyard “Les Chantiers de l’Atlantique” integrated our technology into their operations, igniting our growth in cutting and sheet metal machine software.

From sheet metal to robotics, Alma has consistently expanded its expertise. By 1996, we introduced offline programming solutions for robotic arc welding and 3D cutting, solidifying our position as innovators in the field.

Today, Alma software is trusted globally recognized for unparalleled optimization and advanced functionalities.

Nesting Software as a Game-Changer

Nesting Software: a key to reducing waste and costs

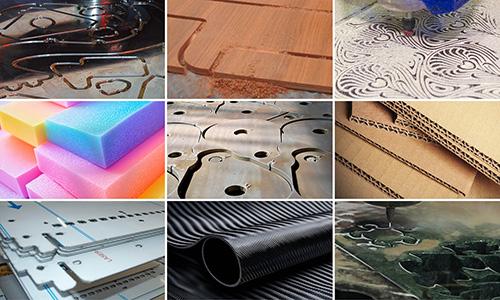

In sheet metal fabrication, as well as wood, foam, or stone production, efficient nesting of parts is essential for reducing material consumption, lowering costs, and minimizing waste.

Without a powerful nesting system, material usage can double, leading to higher expenses, increased energy consumption, and unnecessary waste. This challenge is universal across industries, but it’s especially impactful in sectors where raw materials make up a large portion of production costs—such as in garment manufacturing, where fabric can represent up to 50% of the total cost.

Solving complex nesting challenges with advanced algorithms

For nearly 40 years, we’ve been helping sheet metal businesses boost production efficiency with our advanced nesting software. Our innovative solutions tackle a key challenge: how to optimize raw material usage.

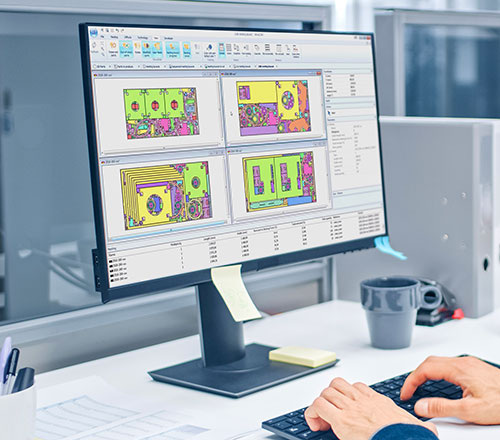

Indeed, manually arranging parts on raw materials is time-consuming and highly complex. The sheer number of possible combinations makes it impossible to guarantee the perfect arrangement without automation. That’s where our nesting algorithms excel. Designed to find effective and efficient layouts within a reasonable timeframe, they rank among the best nesting systems globally.

To achieve these results, we’ve developed and refined day after day intelligent algorithms. They adapt to the unique constraints of different materials and cutting technologies. From metal and wood to paper, stone, and even pie dough, our nesting software is trusted worldwide by both large industrial players and small businesses alike.

This challenge of optimized nesting arises across various industries, and we have the expertise to tackle it—whether it’s metalworking, transportation, shipbuilding, or beyond.

The trusted Nesting company

Alma is the only player on the market to offer these in-house-developed nesting algorithms in different formats: as software components for CAM or ERP providers, and as ready-to-use CAM software for industrial subcontractors. Proof that our algorithms are the most efficient!

We Build It All

What sets Alma apart? We design everything in-house, from our world-class nesting algorithms to our range of CAD/CAM software.

At Alma, innovation and research are the core of everything we do. To craft our tools, we combine deep industry expertise in sheet metal production with the latest innovative technologies.

Alongside our dedicated support team and expert consultants, we boast an in-house R&D team of elite engineers and algorithm specialists. They work tirelessly every day to develop cutting-edge solutions that maximize the performance of our software.

Nesting as Software Components

Powernest: the automatic nesting library designed for software developers

Nesting as On-Prem CAM solutions

Almacam : the Premium CAD/CAM Nesting software range

Nesting as Cloud CAM application

Nest&Cut: The best automatic 2D nesting software in the cloud

Our Nesting Knowledge available for all

For Manufacturing Companies

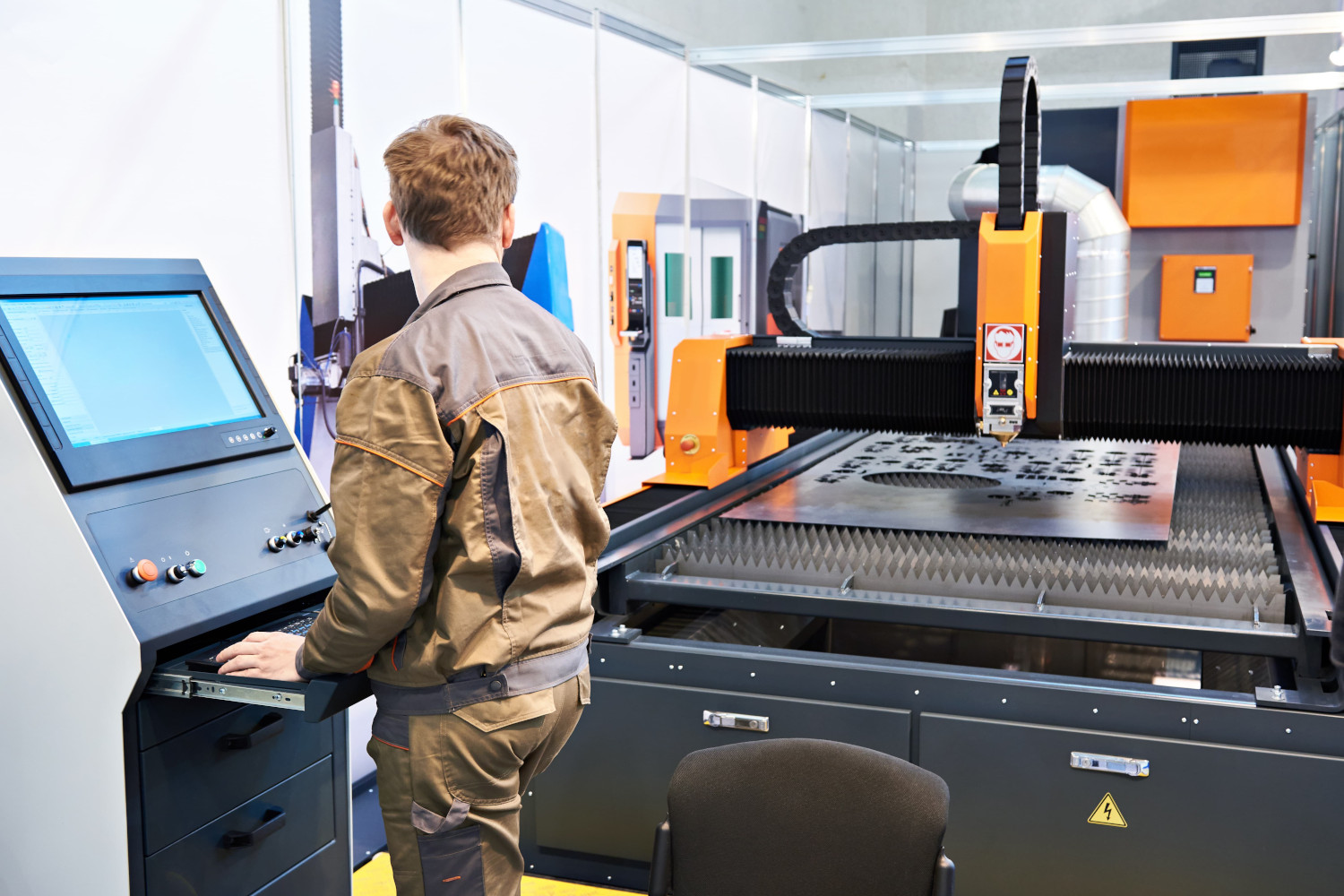

At the heart of Alma’s expertise is Almacam, a powerful CAD/CAM range of software designed to optimize material usage across all cutting technologies. Supporting 2D, 3D and Tube cutting, Almacam incorporates our industry-leading nesting software algorithms that deliver superior results.

For Machine Builders

Alma collaborates with cutting machine manufacturers and robots builders to help them deliver powerful CAM nesting software solutions that elevate their offerings. To make this successful, we provide tailor-made services through reliable partnerships.

For Software Developers

Specially crafted for development teams, Powernest is a robust nesting software library. Offered as a DLL or a cloud-based Web Service, Powernest empowers your developers to seamlessly integrate advanced nesting expertise into your custom applications.