How robotics can address complex tube cutting

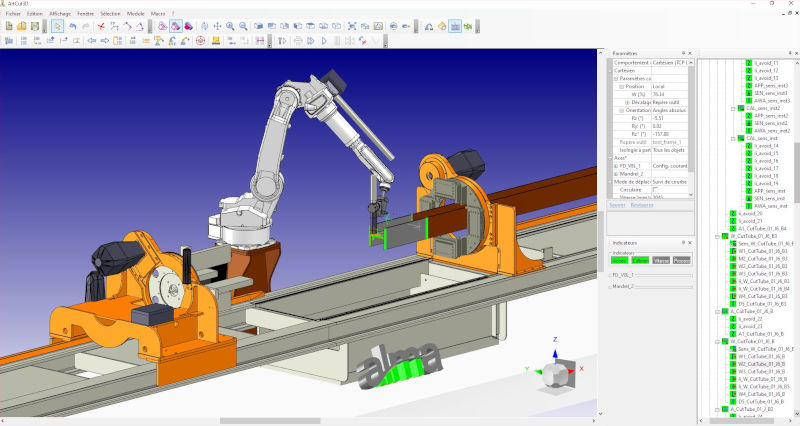

In collaboration with robotics integrators, Alma has developed its Off-line Programming software for robotic tube and profile cutting. This is a specialized market that addresses specific challenges for industrial companies, requiring an advanced hardware and software solution. This application is a great example of how integrators and software providers work together to offer customers a customized solution, adding value through CAM in managing such complex systems.

Why use a robot for cutting tubes and profiles?

The technological progress of the last few years now makes it possible to build highly automated and flexible tube and profile cutting machines, incorporating machinery that is increasingly sophisticated. In the conventional approach, tubes are cut by laser machines with a 5-axis head.

For example, the Mazak and Bystronic machines are highly optimized for laser cutting, offering many specialized options. However, these machines may be restricted when it comes to cutting tubes with small diameters and relatively limited sizes due to accessibility limitations.

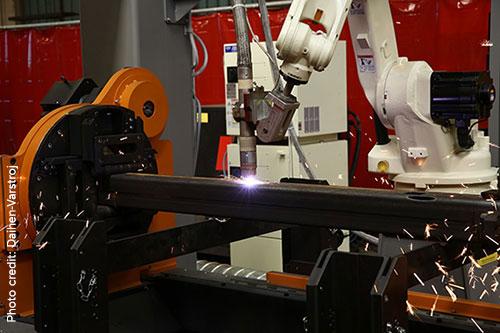

To cut bigger tubes with larger diameters – essentially more than 400 mm – some robot integrators design cutting cells that use robotic arms instead of 5-axis heads.

Since the robots have a working radius of over one meter, they can cut tubes and profiles of any size without any access limitations. Additionally, since these systems use a robot, they offer greater flexibility in the types of parts they can cut. They can cut various types of tubes (round, rectangular, etc.) and profiles (H, I, L, U, etc.), as well as produce chamfered parts from flat sheets.

“For example, one of our clients cuts both bevels on thick plates and tubes with a diameter of 500 mm, or H400 profiles, on the same machine.” explains Nikola Smajgert, Project Manager at Daihen Varstroj, a slovenian company specialized in welding and thermal cutting, partnering with Alma. “For the same cost, these robotic systems offer greater flexibility and productivity than 5-axis cutting.”

Although robotized cutting of tubes and profiles is a niche market, it serves a wide range of industries (such as boiler-making, transportation, agricultural equipment, construction, etc.). Its versatility allows customers to explore new markets by using it in subcontracting work.

How do robotics-based systems for cutting tubes and profiles work?

There are two types of kinematics for robotized tube cutting systems:

- Systems with a rotating mandrel which brings the bars in front of the robot to facilitate cutting configurations. These machines are more complex, but deliver better quality cutting because the torch can remain vertical.

- Systems with no mandrel, suitable for profiles which do not require cutting under the bar. In that case rotation of the mandrel is not necessary and the bar can simply be pushed on rollers. However, this less expensive type of installation may not be suitable for cutting round and rectangular tubes, because robot access is very difficult at the start and end positions, and the molten material may fall onto the torch.

On these installations, plasma replaces the laser source because it has the advantage of being less expensive, effective on large diameters and very easy to integrate onto a robotized arm. Plasma can also cut very thick tubes and profiles, and so overall it is more suitable for cutting profiles.

What about precision?

Although it is still sufficient for cutting in heavy industry, one of the key points is the limited precision of a robot compared to a cartesian head.

To guarantee high precision cutting it is vital to add a trajectory adjustment strategy to compensate for the inevitable part deformations. There are several strategies. Laser or mechanical sensing provides the exact position of a bar’s characteristic points and makes it possible to recompute the trajectories according to the differences measured. Height control makes it possible to adapt the height of the torch during cutting to guarantee a constant sheet/torch distance by measuring the voltage.

No production without a specific software

Although the vast majority of robots are controlled through learning, it is not possible to envisage controlling a robotized shelf-mounted cell with more than 6 axes. Otherwise the precision of the part drawn in CAD would not be guaranteed, and the machine would be immobilized while the program was being created. Nikola Smajgert confirms:

Without a software like Almacam Tube, these machines would be impossible to program.

Almacam Tube is capable of creating a robot program from a CAD assembly, completely automatically. Thanks to powerful tube and profile recognition algorithms to compute trajectories from the CAD model, intelligent nesting algorithms to optimize positioning of the parts on the bar, and algorithms to optimize robot trajectories so as to avoid collisions and singularities, programming of complex machines is child’s play!

For this automation to run smoothly, Almacam has to adapt to the machine, not the other way around. So the software delivers modeling that is faithful to the machine’s kinematics to avoid collisions, take account of inevitable guidance errors and correct them thanks to precise calibration.

In addition, Almacam manages strategies for loading and unloading tubes, opening of jaws, as well as the cutting parameters chosen automatically according to the part’s material and thickness. All these strategies can be customized to suit the individual requirements of each machine. Finally, since Almacam Tube can collect and process production data, it fully integrates industry 4.0 principles.

The importance of collaboration between the integrator and the software provider

From our point of view, for a project to succeed, the integrator’s expertise is more important than the brand of the robot. It is vital for the customer, the robot integrator and the software vendor to work closely together to define and optimize the rules defining how the machine functions.

It is important to work as a partnership from the start of the project, since on these installations it may take some months to progress from initial configuration to delivery to the customer.

For example, the work carried out jointly by Daihen Varstroj and Alma to meet the needs of a customer. Thanks to extensive testing on actual parts, we were able to develop probing strategies to adjust the robot’s positions in response to tube or profile deformations, which are inevitable in bars up to 12 meters long.

Here’s how Nikola Smajgert at Daihen Varstroj sums it up from his perspective as a partner:

We are extremely pleased with Alma's services and expertise in both software and robotics, as well as their deep understanding of all aspects of the metalworking industry. Our technical collaboration with them is highly effective; we are fully aligned. This is crucial for the success of the customer's project.

The Slovenian company Daihen Varstroj specializes in welding and thermal cutting. As a subsidiary of the Japanese industrial robot manufacturer OTC-Daihen, Daihen Varstoj is the group’s center for production and development in Europe. Daihen Varstroj has very strong experience in installing robot cells, plasma sheet cutting systems, and welding generators. Alma and Daihen Varstroj have been working together since 2015 on control systems for robotized cells and 2D cutting tables.