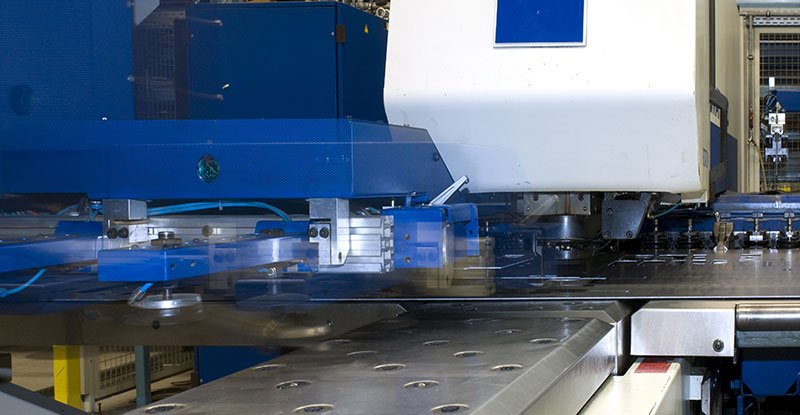

Punching-nibbling

Programming punching-nibbling machines with Almacam Punch

Despite the massive growth in laser cutting over the last thirty years, punching-nibbling remains a major sheet metal technology, all the more so since the machines have become considerably more complex to meet the productivity needs of the industry. The Almacam Punch software is a perfect fit for the specificities of punching-nibbling. It is a highly automated, very high performance CAD/CAM solution, producing numerous varied parts on demand. It interfaces with all types of punching-nibbling machines, combined machines and the associated loading/unloading machines.

The technological process

Punching-nibbling is a process that removes the material by making holes (classic punching) or by cutting inner or outer profiles by means of multiple punching strokes (nibbling). This process combines forward movement of the sheet that is being cut with vertical movement of the cutting tool. The sheet moves under the press containing the tool.

Punching-nibbling is suitable for thin sheets (up to 3 mm), and makes it possible to deform the material (eyes, small folds, stamped parts, threading, etc.). With the same field of activities as laser cutting, but not suitable for complex shapes, this process is faster and more economical for producing simple shapes and multiple holes. In addition, the capacity to include an unloading system makes it possible to completely automate the manufacturing process.

Almacam Punch advantages for punching-nibbling

Almacam Punch’s added value in punching-nibbling technology lies mainly in the software’s powerful automation (tool allocation, machining sequence, nesting, part evacuation, etc.). This makes Almacam Punch a highly productive solution for on-demand production of numerous and varied parts. The software manages all the loading/unloading peripheral systems. It is also perfect for combined machines.

Minimized programming times

- Automatic machining with:

– automatic tool allocation according to the configurable preferences;

– automatic positioning of micro-junctions according to part dimensions;

– hole geometry identification for automatic punch strikes allocation using any kind of tools;

– automatic notching of various shapes and corners,

– automatic evacuation (trapdoor, lift) according to part size.

- Creation and enrichment of the work turret as the parts are prepared.

- Complex machining recording in a database for future re-use on similar parts.

- Automatic nesting and sequencing of common cuts between similar parts.

- Automatic computation of working areas, including clamp areas to work under.

Optimized time cycles

- Optimized sequence respecting the part evacuation and tool order (possibility to configure the sequence type per tool).

- Possibility to perform common cuts between different tools.

- Automatic selection of the tool generating the smallest number of strikes for notching.

- Selection of the most appropriate nibbling tools to minimize the number of strikes.

Significant material savings

- Automatic part nesting under or around clamps

- Specific nesting algorithm for shearing.

- Common cutting of identical or non identical parts, using different tools.

Complete mastering of the technological process

- Management of mounting angles, clamping types, avoidance and accessibility areas according to the turret position.

- Multi-tool or additional turret management in order to increase the number of supported tools (Trumatool).

- Support of any kind of special tools such as roller balls, grooving and deformation tools, kick out and multi-radius tools, etc.

- Optimized management of work areas and clamp repositioning, maximum machining in the last area, automatic positioning of the strut, large part close to clamps, etc.

- Sheet reversal management.

- Supports programmable clamps.

Full integration to sheet metal CAD/CAM to automate the unfolding-cutting-folding workflow

- 3D import of sheet metal folded parts.

- Plan of folding procedure generation for Almacam Bend.

- Supports folding tools used in Almacam Bend to compute the real dimensions of the unfolded part to machine.

Support of related processes and special peripheral devices

- Automatic or manual control of standard evacuation systems (trapdoors, lifts) and manufacturers specific systems (Trumasort, Trumalift, Trumagrip, Amadalift, robotized evacuation etc.)

- Automatic paletting of parts according to configurable grouping criteria.

- Support of punching/laser and punching/ shearing combined machines.

Programming that guarantees enhanced safety around the machine, extended tool life duration and improved quality of manufactured parts

- Management of turret capacity at every step of programming.

- Parts nesting with anti-collision taking into account tool space requirements.

- Tool selection according to part thickness.

- Nibbling using any tool except for round, square, rectangle or oblong tool: for example, banana-shaped, multi radius, trapezoid tool, etc.

- Automatic sheet edge cutting.

- Optimized overlap management in punching (minimum step and overlap control).

- Very late use of deformation tool with automatic head lifting-up or use of deformation tool at the very last moment and with simultaneous head lifting up.

- Automatic management of off-cuts resulting from common cut (the software prevents common cut nesting of parts freeing an off-cut).

- Automatic avoidance of clamps for trajectories with rapid crossing.

- Verification of complete machining of a part: visualization of non-machined material.

- Management of pusher pin to evacuate through trapdoor.

- Controls gripping of the part by lift: position of suction cups in relation to punch strike separating the part and capacity to lift the part according to its weight.

- Common cut guaranteeing evacuation of a single part at a time.

Methods that facilitate preparation and handling in the workshop

- Part machining preparation based on a pre-defined turret model.

- Automatic or manual management of micro-junctions resulting in easier evacuation of complete sheets.

- Evacuation system management (trap doors and lifts).

- Palletizing module providing automatic sorting of parts evacuated by lift.

- Management of loading of sheet by lift and evacuation of skeleton by grip or lift.