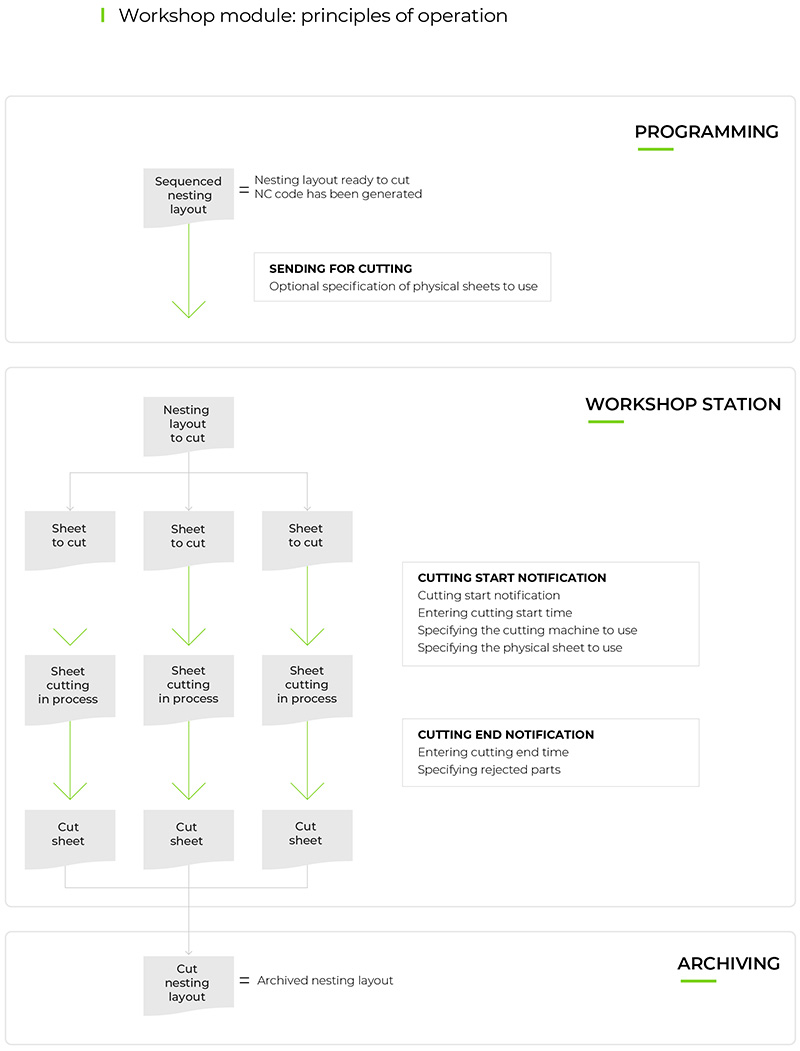

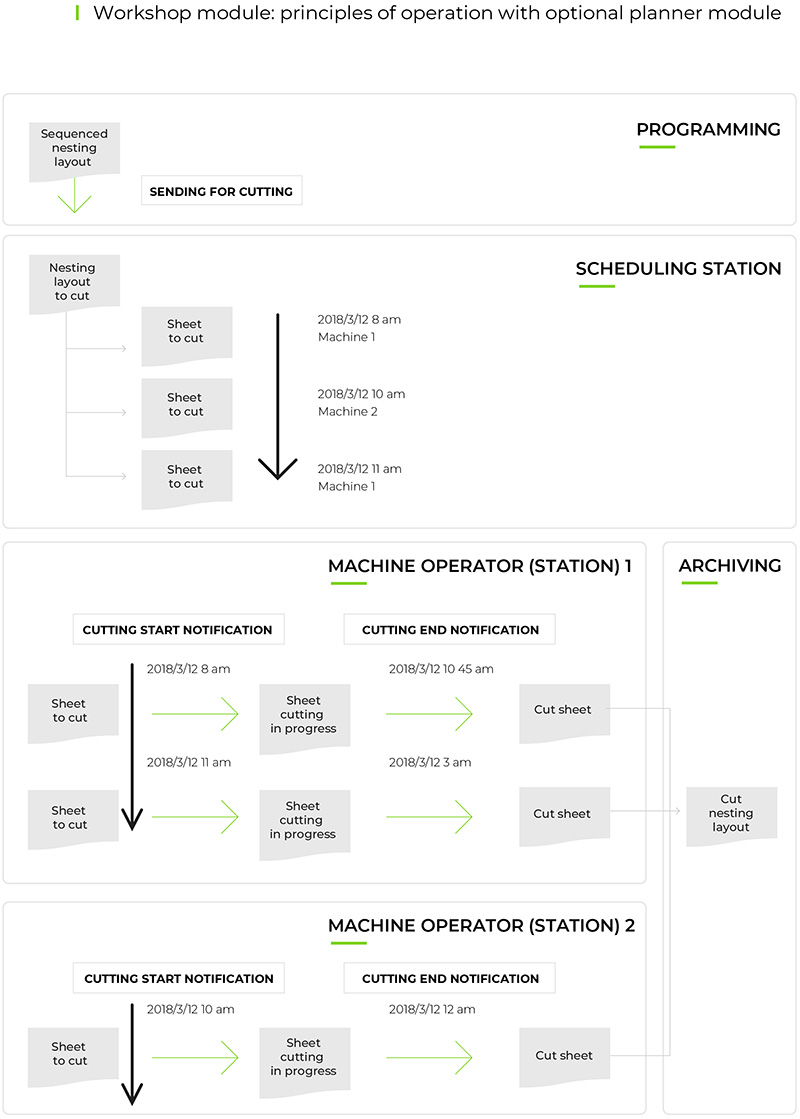

With this Almacam module, machine operators can easily record the start and finish of cutting for each sheet they work on.

Operators get everything they need to plan their cutting: the NC program for each sheet, the corresponding workshop sheet, the estimated cycle time, and the production dates for each part.

If the workshop manager has already scheduled the sheet metal cutting, operators also receive a clear program schedule with the planned start dates, keeping them perfectly in sync with the workflow.

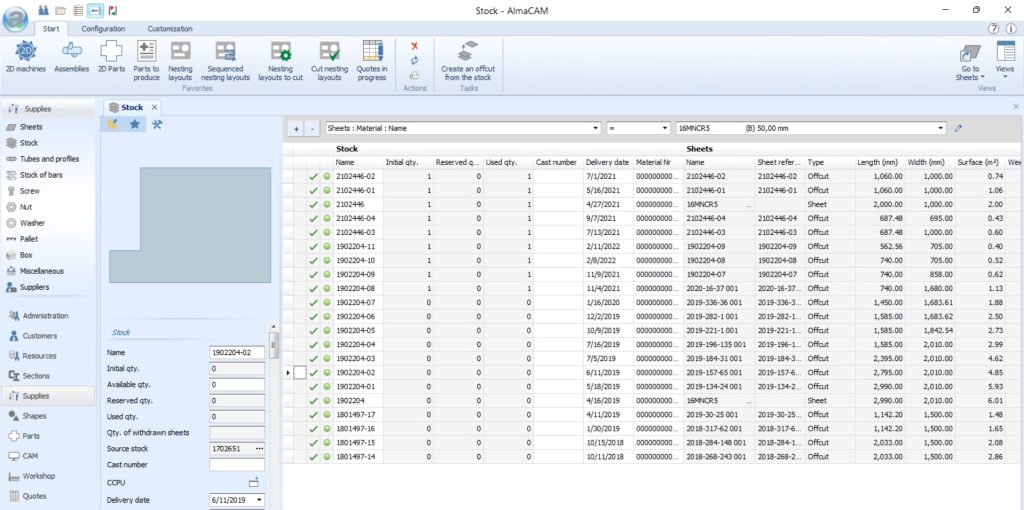

When Almacam is linked to stock management, operators can pick the physical sheet that’s easiest to access in the workshop. Once cutting is done, they can quickly log any scraps or parts that don’t meet quality standards, keeping the process smooth and transparent.

Full Traceability of Parts and Sheets

- Every nesting layout is saved along with the resources used to produce it, giving you full visibility and control. Meeting quality and traceability standards is effortless—you can quickly see which machine and sheet were used for any specific part.

- And at any moment, you can instantly check the status of an order: whether it’s in preparation, in production, and exactly which machine(s) are working on it.

Tools to optimize production and manage cutting operations

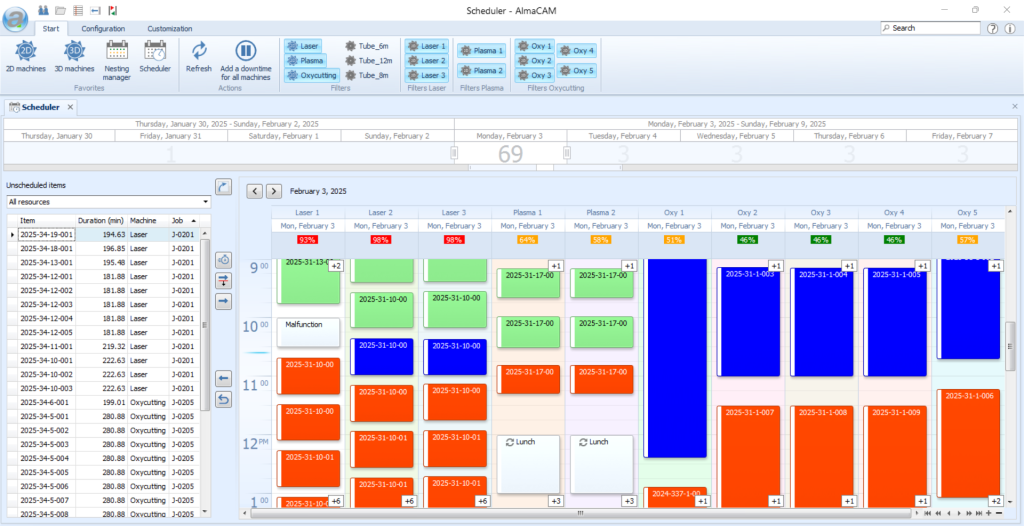

- Visualize machine workloads in real time to spot under-used machines and balance production efficiently.

- Compare predicted vs. actual cutting times to fine-tune machine time calculations.

- Generate dashboards instantly, with clear statistics on machine utilization and performance.

Full control. Full Flexibility

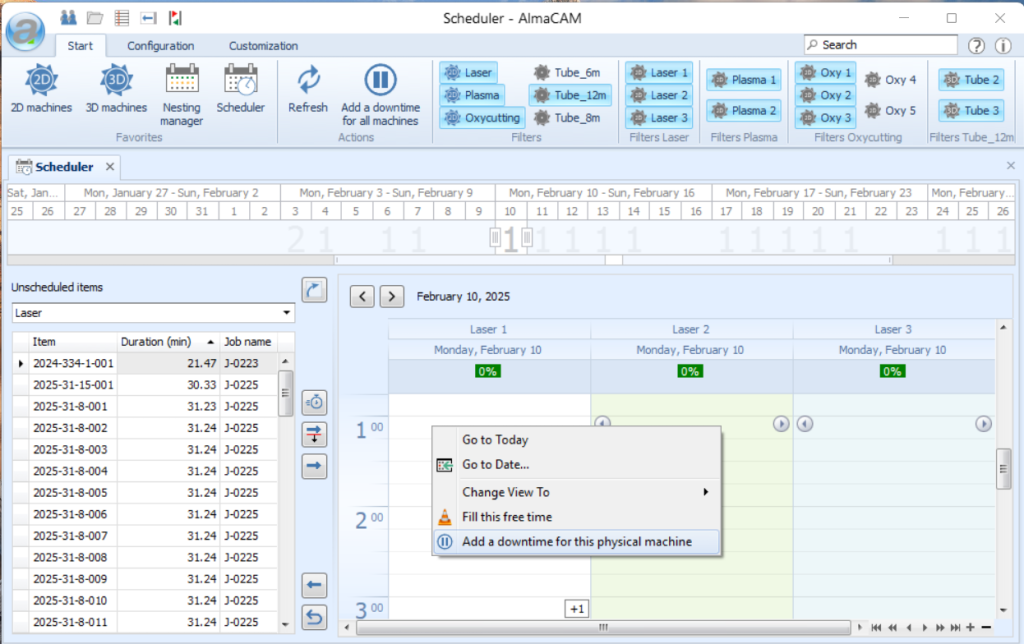

- Keep production running, no matter what. If a machine breaks down, cut your sheets on any compatible machine—without missing a beat.

- Choose your sheets your way. Operators or programmers can pick the easiest-to-reach sheet or the one supplied by the client.

- Full control, full flexibility. Cancel any step: sending for cutting, starting the cut, or closing a nesting layout.

- Simplify large-scale production. Skip the cutting of certain sheets to reduce complexity and stay efficient.

- Plan on the fly. Adjust estimated cutting times, insert urgent orders, and react instantly to unforeseen events.

Complete, Secure, Integrated Workflow

Cut with confidence. Every sheet from a nesting layout follows a clear, error-free process.

Send the NC file to the machine, then declare the start and end of cutting—sheet by sheet—until the layout is complete.

Stay fully updated at every step:

-

Reserve sheets when sending for cutting or at the start.

-

Track produced parts and scrap in real time.

-

Make offcuts available for future layouts, maximizing material use.

Simple guided use

- Drag and drop sheets on the planner to set cutting start times, adjust durations, or switch machines with ease.

- Colors make it simple to see at a glance which sheets are cut, being cut, or scheduled to be cut.

- Tooltips provide instant access to key information for each sheet: program name, material, and predicted cutting time.

Customizable Roles for Your Workshop

- The workshop manager can use the planner to schedule machine operators’ work—or give operators more freedom to decide the cutting order themselves.

- The work environment is fully customizable, with access to data and actions tailored to each user’s role.

- All the essential information is delivered digitally, so operators have exactly what they need: the NC program and workshop sheet to identify the parts to be cut.

Many other possible uses

- Smart automatic planning takes production constraints into account: schedule sheets based on material or size, tools used (for punching or nibbling), production dates, and more.

- Pause a cutting program anytime and resume it later without losing track.

- Manage machine availability effortlessly, considering schedules, breakdowns, and maintenance stops.