Discover what’s new in Almacam v4.0.3

Published on 09/09/2024

As every 6 months, the Almacam Support and R&D teams deliver new features and issues patches. For this new version, we’ve continued our work on optimizing overall performance, such as computation times. In addition, we can highlight those new features that are particularly interesting in everyday use. Read below.

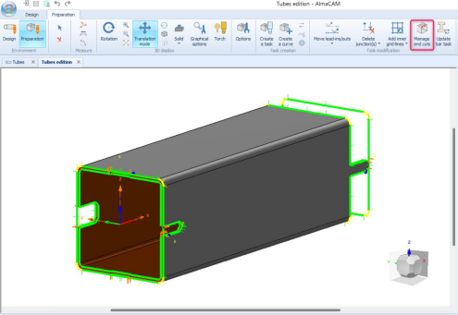

Better shapes recognition on end cuts

A new feature called “Manage end cuts” has been developed to clean up cuts and create common cuts between tubes. This capability automatically splits the cut on a tube’s extremity in several paths:

- The shapes located at the end of the tube (slots and protrusions)

- A straight cut along the tube’s section

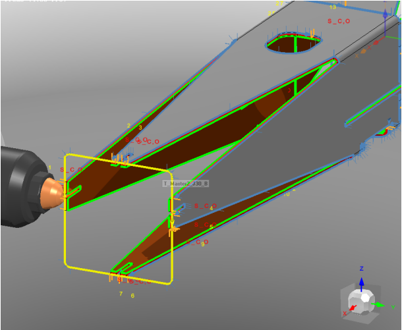

New measurement functions in assembly import

Our customers have reported that when importing the assembly, it should be useful to know the dimensions of the parts. We have listened to them. Almacam 4.0.3 introduces two new measurement functions: linear and angular.

- Linear measures the distance between two reference points.

- Angular measures the angle between two faces.

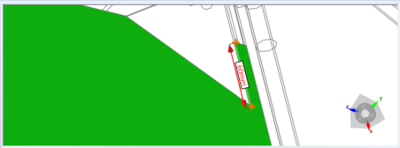

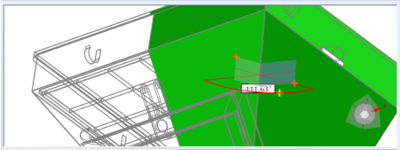

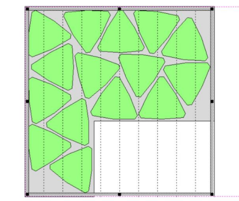

Optimizing nestings on offcuts

New parameters have been added to better take into account the offcut edge gaps. This allows to go even further in optimizing the use of raw materials, with optimized nesting even on offcuts.

Smart turret management for punching machines

Up to now, turrets had to be manually associated to parts. Now this association has become automated thanks to ready-to-use configurations. Another time-saving feature!

In addition, an automatic check is now done to ensure that all parts can be cut with the same turret.