Some companies rely on in-house solutions for making quotations, or program laser machines directly on the CNC. As the number of RFQs increases, so does the risk of oversights and errors. Charvin Industries chose Alma’s quotation software to address both these issues. A story based on an article written by Arnaud VACHERAND, editor of the french magazine Métal Industries.

To cope with the increasing volume of orders, we implemented Alma solutions. We can now manage our quotes more quickly, organize production more efficiently and rationalize the use of a single sheet for inserts, while minimizing waste.

Jérémy PLOTTON, Président de Charvin Industries

Charvin Industries' expertise

Anchored in the industrial basin of Saint-Etienne in France, cradle of the mechanical and metallurgical industries, Charvin Industries manufactures metal parts and assemblies. Within a 4000 m² industrial building, 150 machines and a unique know-how, the company answers requests for press (cutting / stamping), laser cutting, bending, machining, sheet metal work (welding / bending). With a 100-year history, Charvin has acquired expertise in the manufacture of parts from a few grams to assemblies weighing several hundred kg. Charvin works with over 500 industrial customers in industries such as railways, construction, renewable energies and aeronautics.

The challenge : the bottleneck of quotations

Charvin’s constant growth and the development of products for construction professionals have increased the need for costing and laser monitoring. While an experienced user was able to meet demand by managing quotations generated via the Excel spreadsheet, the exercise quickly became unmanageable with the thousands of references processed by the company; the responsiveness of this strategic position suffered.

The solution : Almaquote with a tailored configuration to meet specific requirements

Charvin Industries has been using the Almacam CAM suite since 2007. In 2020, Almaquote, the quotation module, was implemented to speed up the entire process from quotation to production.

Almaquote is based on the settings recommended for the Mazak machine, but users can modify the features to suit their specific needs. This is also the case when cutting sheets with a thickness below the manufacturer’s recommendations, such as 0.5 mm.

“Today, we can upload any types of 3D files from CAD or NC files, a powerfull option available with the Alma suite“. Parts are automatically unfolded in Almaquote, then files are checked to ensure their feasibility and to propose an alternative solution to the client if there is a difficulty. Once the project has been validated and accepted, “we apply cutting parameters according to material and thickness, and Almacam calculates the surface area of the material needed, as well as the cycle time”.

Data about cycle times and material requirements are exported from Almacam and Almaquote to the ERP system to produce the quotation sent to the customer. All subsequent operations are then integrated into the quote.

The results: faster quote and production management, reduced off-cuts

With our new Mazak laser, our digital bending machine and Alma's software, we've entered a sheet metal market in which we weren't a major player. Whereas previously, we knew how to work well with 4 to 5 weeks lead times, we've now learned to work well within 48 hours,” says Jérémy Plotton.`` shares Jérémy Plotton.

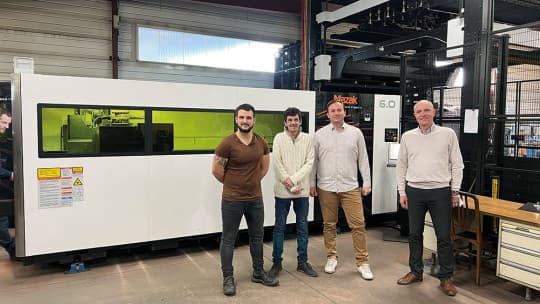

In front of a Mazak laser machine, Louis Ruchot and Laurent Taite, quotation managers, and Jérémy Plotton, President, of Charvin Industries and Régis Lacroix of Alma

Charvin Industries is equipped with 2 workstations dedicated to sheet metal parts:

- the first for file validation and costing,

- the second, in the workshop, for retrieving information and launching production orders for the laser machine, optimized for the most economical and efficient use of sheet metal stock, taking into account several customers if necessary.

All this is done without having to re-enter any information.

The programmers gather all the files, upload them to Almaquote, and as if by magic, all the parts are generated with the correct quantities and thicknesses, ensuring nothing is overlooked. Tasks that used to take me hours to complete before starting production are now accomplished in record time.