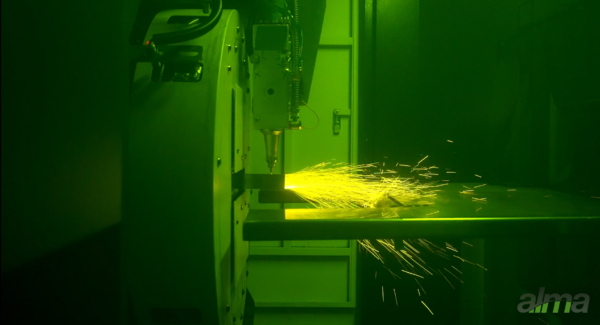

In the heart of Italy’s metalworking industry, Steeltec SRL was grappling challenges in meeting demands and a desire to deliver highly precise metal-cut profiles to its customers. By adopting Almacam suite, the company has turned its laser tube cutting operation into a fast, flexible, and precise production line—cutting quote times and maximizing machine efficiency.

Interview of Cristian Minioia

The founder of Steeltec and a passionate advocate for technological advancement, explains the company’s journey and how Alma helped boost their efficiency, flexibility, and productivity.

You can buy the best laser machine in the world, but without a good software, it’s not efficient.

Cristian Minioia, CEO of Steeltec SRL

Steeltec SRL, a metalworking company embracing the power of innovation

Steeltec SRL, is an italian subcontracting metalworking company with over 15 years of experience. The company offers a wide range of services, from simple laser cutting and tube processing to complex turnkey projects, particularly in the agri-food sector. What began with basic home equipment has now evolved into a tech-forward operation leveraging the latest in Industry 4.0 machinery and software.

Despite their growth, Steeltec faced operational roadblocks. Manual quoting processes and limited software for machine programming were slowing them down—especially as demand for fast, customized tube cutting increased.

The challenge: automating the flow of precision cutting processes

As Steeltec expanded into more specialized subcontracting services, they needed to improve speed and precision in laser tube cutting. The challenge wasn’t just about investing in new machinery—it was about finding the right software to unlock the full potential of that machinery.

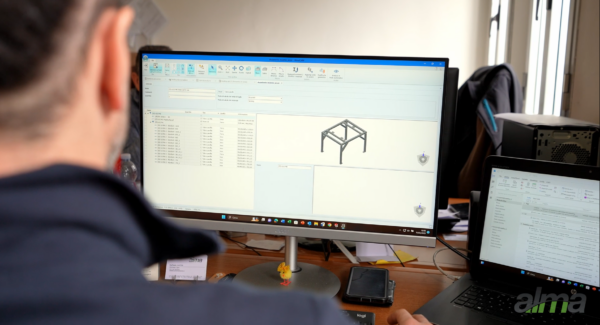

Using only the machine manufacturer’s software for programming was becoming an obstacle, while their outdated quoting process couldn’t keep up with complex requests. Steeltec needed a solution that would automate and accelerate the complete production lifecycle.

Initially, after installing the machine, we were using the manufacturer’s software, but once we adopted Alma’s software suite, everything changed—with greater efficiency and technical office programming—which was a very important shift for our business.

When manual processes limit growth

As Steeltec expanded its services and took on more complex projects, the team quickly realized that their existing tools were holding them back. The machine manufacturer’s programming software and traditional quotation methods were no longer enough to support their growing workload and client demands.

This setup led to several challenges:

- Limited efficiency in programming: the manufacturer’s software lacked the speed and flexibility Steeltec needed for day-to-day operations.

- Delayed production times: without the right tools, parts were cut, but not always on time or with optimal material usage.

- Cumbersome quoting process: the old quotation method made it difficult to respond quickly and confidently to customer requests.

4 tangible benefits Steeltec gained

To overcome these challenges, Steeltec SRL has implemented several modules of the Almacam suite :

- Almacam Tube

- Almaquote

- Assembly2cam

Cut programming time and boost machine utilization

With Almacam Tube, Steeltec now automatically generates optimized cutting programs for complex geometries. The software supports all types of machines and includes simulation, nesting, and trajectory optimization—ensuring maximum efficiency from every cut.

Faster quote generation and with confidence

Thanks to Almaquote, the accuracy of Almaquote matches Steeltec’s previous manual methods—giving them faster turnaround without compromising precision.

“Almaquote is very important and effective. It gave us a huge advantage, allowing us to be in the market with the right estimation, knowing that we’ve verified it against our old quotation methods.”

Automated Assembly Management

The Assembly2cam module simplified the import of CAD assemblies and allowed automated identification of parts for cutting or quotation.

“I consider Assembly2cam as very strategic in our development and production process. The module allows us to take a STEP file of an assembly and automatically generate laser tube cutting programs for some parts and send others to the quotation tool.”

Ready for the Future

With Alma’s tools in place, Steeltec is now positioned for future investments and innovation, with a digital foundation that supports scalability and Industry 4.0 standards.