Operating in a highly variable heavy plate cutting environment, Gabrielli Divisione Lamiere faced increasing complexity in job preparation, material optimization, and cost control. Manual processes made it difficult to align quotations with production realities.

With Almacam and Almaquote, Gabrielli streamlined its workflow, achieved up to 6% material savings, and accelerated preparation times.The result: faster operations, more reliable quotations, and improved profitability.

Interview of Carlo Grosselle

Carlo Grosselle, Operations and Commercial Director

A legacy steel jobshop reinvented through digital innovation

For more than 60 years, the Gabrielli name has been synonymous with excellence in steel distribution and processing in Italy. What began in 1954 as a small warehouse in the town of Cittadella has grown into Gabrielli S.p.A., a leading industrial group processing and selling up to 500,000 tons of steel annually across three divisions.

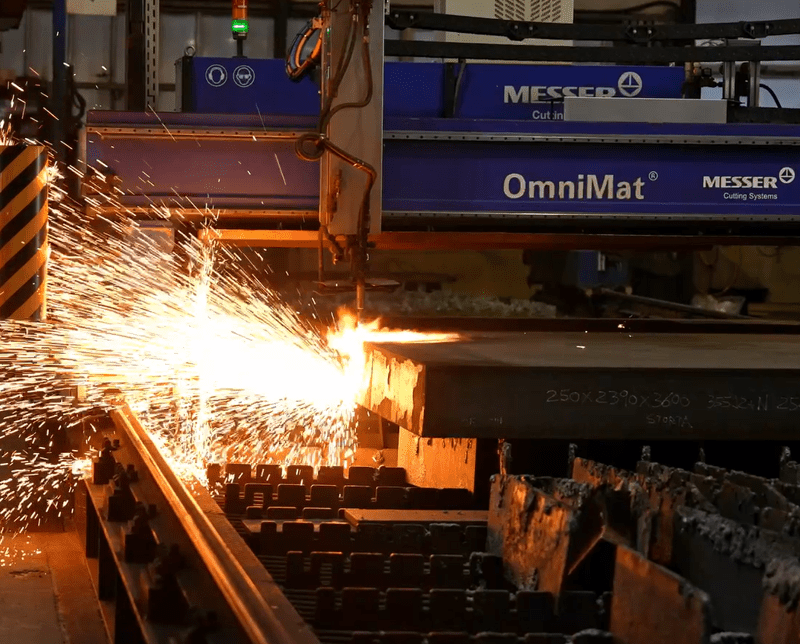

Among them, the Divisione Lamiere Grosse (https://www.gabrielli.it), founded in 1988, is dedicated to heavy plate processing. With its combination of cutting power and industrial know-how, it has become a benchmark for precision work on large steel plates.

Today, this heritage fuels a new ambition: transforming traditional cutting operations through digital intelligence.

A complex production environment demanding precision and agility

The Divisione Lamiere Grosse operates in a highly variable, non-serial production context. Every customer order is different and each requires the perfect balance of:

- material optimization

- cutting accuracy

- speed of preparation

- production flexibility

With oxy-fuel cutting systems, plasma cutting systems and press brakes, the division manages a continuous flow of custom-made parts destined for industries such as construction, heavy machinery, transportation, naval manufacturing, and infrastructure projects.

But complexity brings challenges: identifying shapes, preparing nests, choosing the right plates, estimating scrap and ensuring consistency between quotations and production.

These tasks were increasingly time-consuming and essential to profitability.

To remain competitive, Gabrielli needed a smarter, more automated, and perfectly integrated cutting workflow.

The turning point: adopting Almacam to optimize every step

After evaluating solutions, Gabrielli chose the Alma’s software suite for its ability to improve both commercial and production activities within a single coherent ecosystem.

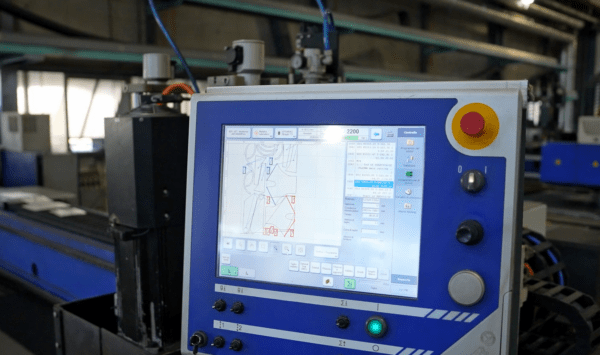

Almacam helps Gabrielli achieve advanced nesting, automatic part identification, plate optimization and machine programming bringing reliability and efficiency to daily production.

Almaquote provides fast, accurate cost estimation based on real material usage and precise scrap forecasting, enabling the sales team to generate reliable quotations in several minutes

An investment that quickly delivered measurable benefits

1. Faster Preparation and Job Identification

Almacam’s automatic recognition of customer geometries drastically simplifies the preparation of cutting plans. What previously required manual analysis is now completed in a fraction of the time.

2. Smarter Nesting and Material Savings

With Almacam’s nesting algorithms, plate usage at Gabrielli has improved significantly, reducing material consumption by 5–6% a major gain in heavy plate operations where every centimeter counts.

3. Accurate Quotations with Real Data

Now, Gabrielli ‘s commercial team is able evaluate the true material requirements and anticipate scrap before production begins. The benefits achieved contribute to improved profitability:

- more reliable prices

- consistent margins

- faster response times to customers

4. A Seamless Link Between Quotation, Production, and ERP

The integration between the Almas’ tools and Gabrielli’s ERP creates a unified flow of information. No data duplication, no errors just a smooth transition from customer request to cutting execution.

5. Increased Productivity Across the Cutting Lines

With more efficient nesting and reduced manual tasks, machines run more consistently, and workflows are streamlined.

The division gains agility and can absorb more orders without increasing lead times.

A Partnership Supporting Continuous Improvement

Beyond the software itself, Gabrielli underscores Alma’s high-quality technical support.

The collaboration includes:

- remote troubleshooting with rapid response times

- on-site interventions when required

- progressive adjustments to adapt the solution to Gabrielli’s evolving needs

This long-term partnership ensures that the division continually improves its processes and remains aligned with customer expectations.

A Modern Evolution for a Company Built on Industrial Excellence

By integrating Almacam and Almaquote, Gabrielli Divisione Lamiere Grosse has successfully united its industrial heritage with advanced digital technology.

The result is a modern, efficient, and highly optimized cutting workflow that strengthens the division’s competitiveness while reducing waste and improving profitability.

Alma and Gabrielli: transforming heavy plate processing into a smarter, faster, and more sustainable operation.