Over the years, SILCA has grown from a small workshop into a full-service metal components manufacturer. As assembly complexity increased, welding became a major bottleneck: manual robot programming was too slow and kept the cell idle.

By adopting Almacam Weld, SILCA now programs its robots offline directly from 3D models, without stopping production. This approach drastically reduces programming time, keeps welding in parallel, ensures high precision, and makes even small batches economically viable.

Interview of Fabio Forigo

Fabio Forigo, Director of SILCA

SILCA at a glance: from workshop to full-service metal manufacturer

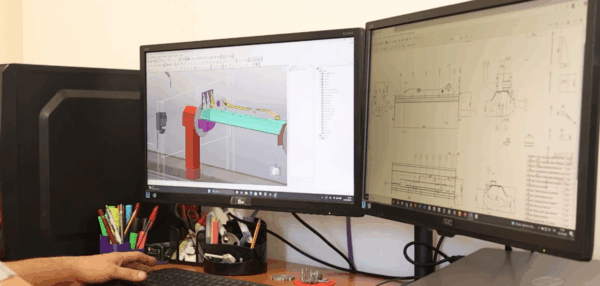

Founded in 1993, S.I.L.C.A. S.r.l. (https://www.silcait.com/) is an Italian metalworking company based in Nogara (Verona). Starting with simple cutting and bending operations, it progressively integrated a complete in-house production chain: sheet and tube laser cutting, bending/rolling, manual and robotic welding, machining, assembly, finishing, and surface treatments such as painting and galvanization.

Today, operating from a 24,000 m² site with 300 m² dedicated to industrial development, SILCA delivers fully finished, ready-to-use products, providing a true 360° service.

A dual challenge: eliminating the welding bottleneck and overcoming the limits of manual robot programming

As SILCA grew and began producing increasingly complex assemblies—especially for the agricultural machinery sector—the welding department quickly became a major production bottleneck. To meet rising demand while maintaining high quality standards, the company needed to modernize its workflow with a more advanced automation solution.

Installing a robotic welding system was a decisive step forward, but it soon exposed a new obstacle: manual robot programming proved slow, time-consuming, and a significant limitation to overall productivity.

To fully capitalize on its investment in robotics, SILCA needed software capable of automating and simplifying programming, reducing downtime, accelerating job setup, and ensuring consistent, high-precision results.

Taking SILCA’s robotic welding to the next level with Almacam

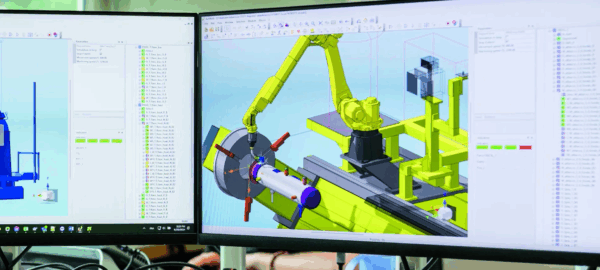

After identifying the limits of manual programming, SILCA began searching for a solution that could modernize the entire welding workflow. Almacam Weld quickly stood out for a decisive capability: the ability to start directly from a 3D model and program the robot offline, without interrupting production. This marked an important milestone in SILCA’s digital transformation with Almacam Weld.

The two modules for Robotic Cutting and Robotic Welding are linked, they communicate seamlessly. What’s done in tracing and cutting transfers directly to welding, with no delay.

Almacam Weld immediately stood out because it allows us to start from a 3D file and program offline. Programming time has dropped drastically, especially because we can program while the cell is still running.

But Almacam Weld’s value for SILCA goes far beyond programming features. By enabling offline programming directly from 3D data, the software has created a seamless digital thread from design to robotic welding, ensuring consistency, precision, and speed at every stage of the production process.

An investment that quickly delivered measurable benefits

1. Drastically reduced programming time

Thanks to offline programming, SILCA can prepare new welding jobs while the robot continues operating. The result: zero downtime and a much faster production flow, even for complex assemblies.

3. Advanced 3D reverse-engineering capabilities

SILCA designs and validates directly in 3D. With Almacam Weld, every component and fixture can be assembled and checked for collisions before production begins, ensuring a safe, precise, and fully predictable process.

2. True parallelization of work

Programming and production now run in parallel. Operators can prepare incoming parts while the robot completes ongoing welds, maximizing productivity and significantly reducing lead times.

4. A decisive commercial advantage

The ability to confirm feasibility and estimate costs in real time has transformed SILCA’s commercial approach. Even small batches – previously unprofitable due to long programming times are now fully viable, giving the company greater agility and competitiveness.

Looking forward: innovation that lasts

With Almacam Weld, SILCA has turned a critical point in its production process into a measurable competitive advantage: faster cycles, more stable processes, and greater operational flexibility. A clear demonstration of how an advanced OLP platform can transform the complexity of robotic welding into efficiency, repeatability, and complete process control.