In the heart of Italy’s Veneto region, SOLME, a family-run company specializing in boiler-making, has redefined precision metal fabrication for the food, chemical, and pharmaceutical sectors. By integrating Alma’s software suite into their unique robotic unit, SOLME has brought new levels of automation, quality, and efficiency to thick sheet metal cutting and welding, even for large and 3D parts.

Interview of Paolo Giuriati

Paolo Giuriati, Owner and Manager of SOLME

SOLME: A boiler-making company driven by innovation

Founded over 40 years ago in San Biagio di Callalta, SOLME is deeply rooted in Italy’s boiler-making tradition. What began with manual craftsmanship has evolved into a cutting-edge production environment, equipped with robotic systems and smart programming. The company’s strength lies in its ability to produce large systems and components for highly demanding sectors, often working with thick, complex sheet metal structures.

The challenge: bridging craftsmanship with robotics

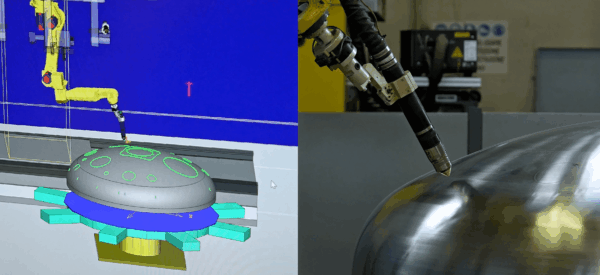

By 2017–2018, SOLME had the vision to automate complex parts of their sheet metal cutting and welding process, without losing the precision and adaptability of human craftsmanship. The result: a robotic unit with two dedicated workstations. One focuses on tracing and cutting flat and 3D sheet metal parts, and the other on welding. Both individual and assembled components.

But machines alone weren’t enough. The real challenge? Finding a software solution capable of orchestrating the full workflow, from CAD to cut to weld, as one unified system.

Almacam : the brain behind the machine

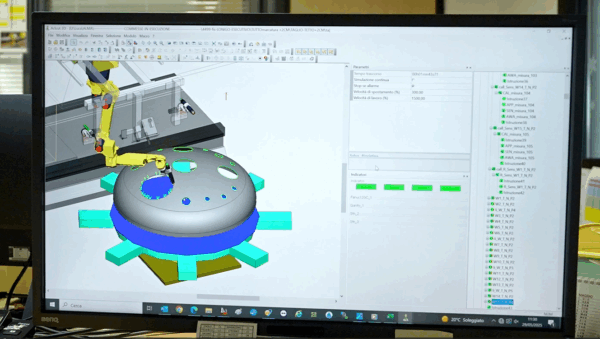

After evaluating several options, SOLME chose Alma’s software suite for its unique ability to fully integrate cutting and welding processes. With Almacam 3D for tracing and cutting, and Almacam Weld for welding, the software forms a seamless digital thread from design to production.

The two modules for Robotic Cutting and Robotic Welding are linked, they communicate seamlessly. What’s done in tracing and cutting transfers directly to welding, with no delay.

The Alma team didn’t stop at delivering out-of-the-box software. They provided SOLME with tailored customizations to match the unique specifications of their robotic system, something rare in partnerships between large software companies and smaller manufacturing firms.

4 key benefits SOLME gained with Almacam

1. A fully integrated workflow

By using Almacam 3D and Almacam Weld together, SOLME controls its entire robotic unit from a single software platform. There’s no break between phases, boosting efficiency and reducing human error.

3. Enhanced professionalism

Automation at SOLME hasn’t replaced people, it’s elevated them. The robotic system complements the team’s skills, making production more professional and future-ready.

2. Optimized production of large, 3D parts

SOLME’s work often involves large or irregularly shaped sheet metal. Alma’s software handles complex geometries with ease, enabling accurate cutting and high-quality welding even for non-standard components.

4. Strong experience of Alma in shipbuilding

Alma’s responsiveness and willingness to co-develop solutions with SOLME was unexpected and invaluable. Despite being a small company, SOLME received top-tier support, showing Alma’s commitment to every client.

Looking forward: innovation that lasts

Installed in 2019, SOLME’s robotic production system remains unique in the boiler-making industry. It’s a testament to what happens when vision, tradition, and the right technology come together.

This is an extremely innovative system. Even today, it remains one-of-a-kind in our sector — and Alma helped make that possible.

SOLME continues to lead the way in high-value boiler-making, proving that even in a traditional field, bold innovation can reshape the future.