Thiévin, a family-owned SME, specializes in designing and manufacturing a wide variety of products for the agricultural, public works, and environmental sectors. With extensive experience in robotic welding, the company sought to streamline the welding of large complex parts.

To achieve this, it invested in a Yaskawa system featuring 2 stations and 3 robots that can collaborate on the same part. It soon became evident that robotic welding programming with OLP was the only practical solution for handling such parts efficiently while dramatically reducing programming time.

With Alma's OLP software, we estimate that we can reduce the manufacturing time for these parts by 2.5 to 4 times compared to manual welding.

C.Duret, Maintenance Manager at Thievin

Thievin, a modern company crafting quality products for agriculture and public works

Founded in the early 1980s in Saint Mars la Jaille, in France, Thiévin began as a manufacturer of agricultural machinery and trailers. Over time, the company diversified its offerings and experienced significant growth, driven by its customer-focused approach and adaptable industrial processes.

Today, Thiévin designs and produces a broad range of products, including agricultural trailers, skip buckets for public works, hay-bale flatbeds, handling accessories, buckets for front and telescopic loaders, skips, containers, and crates.

With a workforce of 160 employees, the company has invested heavily in cutting-edge industrial equipment. Its facilities feature a laser cutting machine, shearers, press brakes, a pipe-forming bell, welding robots, semi-automatic welding units (for steel, aluminum, and stainless steel), a machining center, and a paint booth.

A bespoke robotics system to weld very voluminous parts

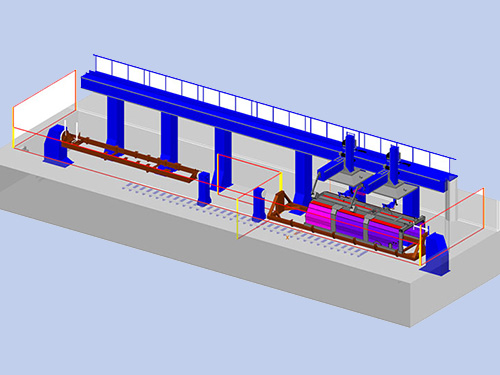

Thiévin started to use robotics almost 15 years ago. Today the company is equipped with three Yaskawa (Motoman) robotic welding systems . The latest system was commissioned recently, and is one of the few systems of its type used in France. It comprises two robots installed on a 26 m gantry capable of operating on two stations. Both robots work on the same part, using synchronized sequences and instructions. Each robot has three external X, Y, Z axes (the three translation axes of the gantry: transverse, longitudinal, vertical) and two positioners, each with a single rotation axis, for a total of 4 external axes on each robot. This highly sophisticated installation is designed to weld very large or very voluminous parts, which up to now were welded manually. The objective is to minimize manufacturing times. The two robots weld simultaneously, and while they are working on one station, the part can be loaded or unloaded on the second station.

So how do I program this complex robotized system? It would be very difficult to program these types of parts using the learning approach, because they are so big, and because it is difficult for operators to reach certain areas. In addition, it is much more complex to program “twin” robots by learning: in this specific case, it would be necessary to manage 19 axes simultaneously! This would end up representing several weeks of programming… “ So it was clear to us that off-line programming would have many advantages” explains Cédric Duret, the maintenance manager, leading the robotics project, “enabling us to program in the best possible conditions using the CAD model, to calmly define the simultaneous movements of the two robots thanks to simulation, and to very significantly reduce the programming time, while also freeing up productive time on the robot. Especially as the relevant parts are produced in small production runs, or even one by one “

Cédric Duret and his managers were familiar with the principles of off-line programming and also with Alma, one of the only independent vendors of this type of software. So they wanted to look in detail at Alma’s solution, once the robotics project had been defined. They quickly realized that the Alma’ welding software would solve all their problems.

So it was clear to us that off-line programming would have many advantages, enabling us to program in the best possible conditions using the CAD model, to calmly define the simultaneous movements of the two robots thanks to simulation, and to very significantly reduce the programming time, while also freeing up productive time on the robot.

Successful launch of off-line programming

Two key steps to ensure successful off-line programming were completed: mechanical calibration of the robotics system with the assistance of Yaskawa and Alma technicians, followed by software calibration (updating of the virtual system to match the real system) with Alma and the personnel from Thiévin in charge of the project. In parallel, in-depth software training was provided, followed by a second phase to optimize the programming and the welding parameters. Cédric Duret underlines the importance of Alma’s support during the start-up phase in order to ensure the project runs smoothly, in close collaboration with the robot manufacturer. The person specialized in off-line programming has strong experience in robotics, which is an additional success factor.

The company has not yet had time to see the benefits of this new robotized system and off-line programming, but has great hopes for the Alma tool. “Bearing in mind everything we’ve seen and learned about this software, we hope to achieve considerable gains in programming time” says Cédric Duret.

Thanks to this new investment in robots and software, we estimate that the manufacturing time for these parts will be reduced to between one-fourth and five-eighths of the time previously required for manual welding.