Are you struggling with rising material costs, tight deadlines, or production inefficiencies in your sheet metal business? These challenges are all too familiar in the metal industry. Precision demands, reducing waste, and meeting client expectations can often feel like uphill battles, especially when relying on outdated tools or manual processes.

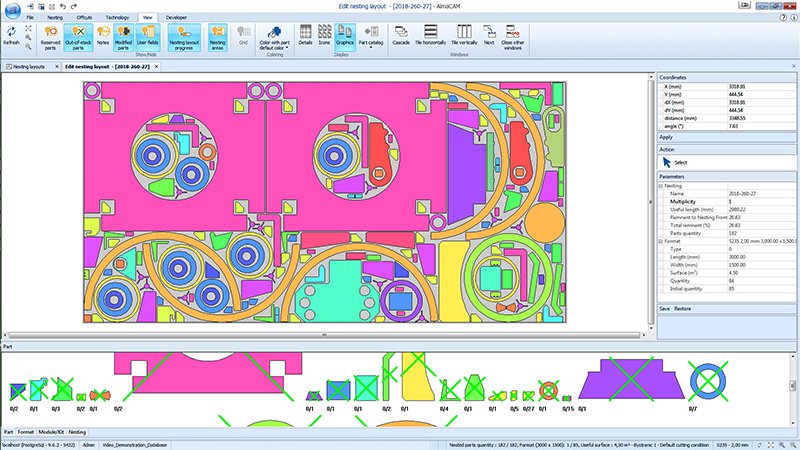

Almacam software suite helps solve these challenges with powerful CAD/CAM capabilities, including the most advanced nesting in the world.

Rely the best CAD/CAM nesting software for efficient production

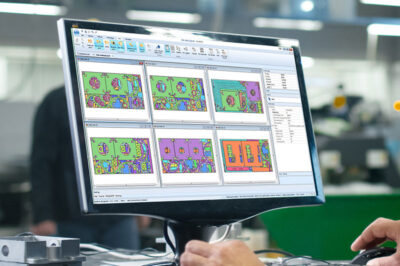

Almacam is a comprehensive CAD-CAM software that manages the entire sheet metal manufacturing workflow. It provides solutions for:

- 2D cutting for laser, plasma, oxy-cutting, water-jet,

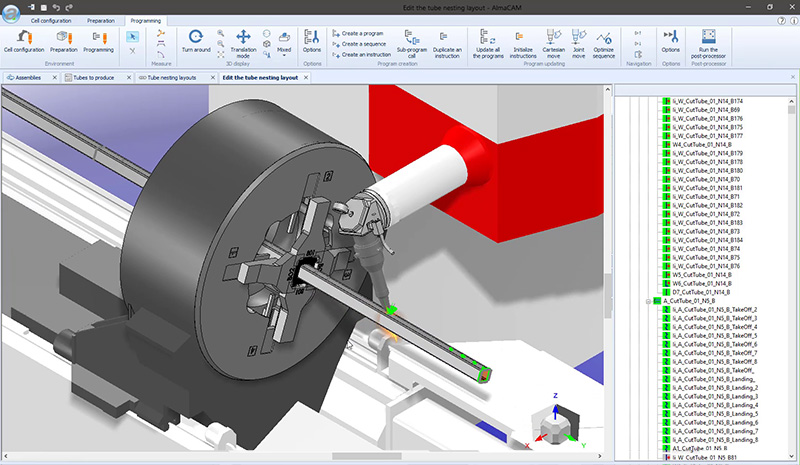

- Tube and Profiles cutting,

- 5-axis and 3D cutting,

- Punching,

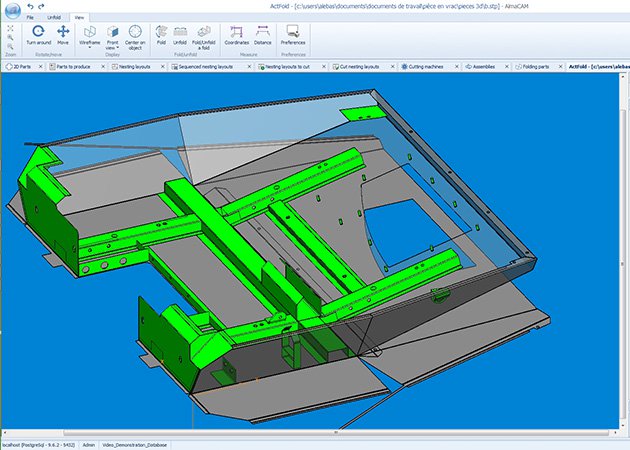

- Bending,

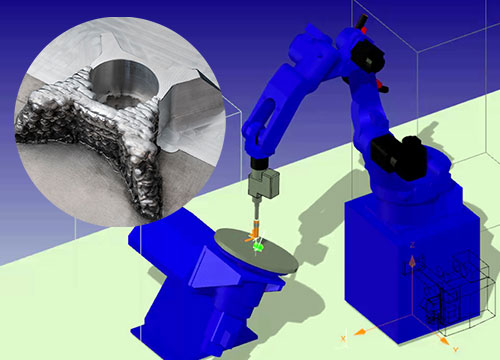

- Offline Programming for Welding Robots.

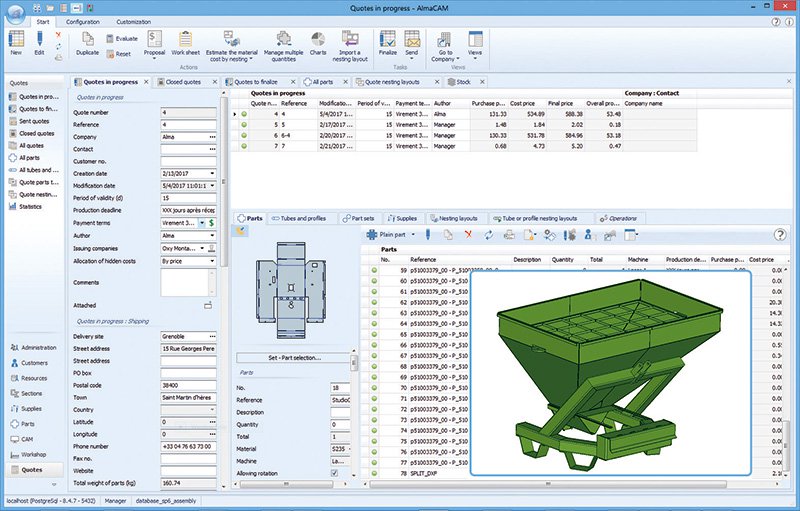

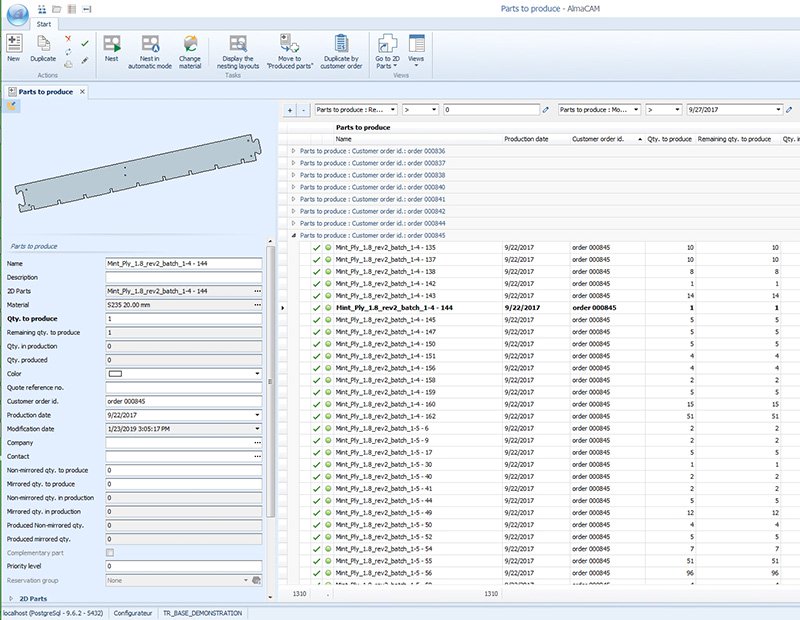

Additionally, Almacam includes modules for quotation, production planning, and integration with other information systems (MES, ERP…) , making it an ideal solution for efficient industry 4.0 workshops.

Alma, leader in CAD/CAM solution for 45 years

Almacam software is fully developed by Alma company, that has been a recognized leader in nesting and CAD/CAM solutions. For over four decades, Alma has been at the forefront of creating powerful nesting algorithms and innovatione solutions for the sheet metal industry. Thus, Almacam is the all-in-one flexible solution to make your production more efficient, precise, and sustainable.

What is CAM software?

CAM software (Computer-Aided Manufacturing) is used to control CNC machines (Computer Numerical Control) by converting CAD designs into precise machine instructions. It automates tasks like 2D cutting, 3D cutting, laser cutting, plasma cutting, oxycutting, and waterjet cutting, enabling manufacturers to produce accurate parts with minimal waste and reduced lead times in industries like sheet metal working.

The complementarity between CAD and CAM

While CAD (Computer-Aided Design) software focuses on detailed product design, CAM software translates these designs into instructions for CNC machining. The seamless integration of CAD/CAM software ensures smooth transitions from design to production, optimizing manufacturing processes and increasing your company’s competitiveness.

Benefits of choosing a Top CAM software solution

A robust CAD-CAM software like Almacam provides numerous advantages for manufacturers:

- Reduce material waste: Advanced features with true-shape nesting help arrange parts efficiently, cutting costs and minimizing raw material usage.

- Save time and boost productivity: Automating tasks and integrating design with manufacturing eliminates bottlenecks and accelerates production workflows.

- Achieve precision: Whether working with flat sheets or complex tubular shapes, Almacam’s automation features ensure accurate results every time.

- Enhance competitiveness: With tools that address daily manufacturing struggles, Almacam helps you stay ahead in a fast-moving market.

Frequently Asked Questions on CAD, CAM and Nesting

What is the role of CAM software in manufacturing?

CAM (Computer-Aided Manufacturing) software plays a crucial role in modern manufacturing by transforming design data into machine instructions. It automates the creation of toolpaths, optimizing processes like parts placement, cutting programation. This ensures precision, reduces human error, and enhances production efficiency. CAM software also enables the simulation of machining processes, helping to identify potential issues before actual manufacturing, saving time and resources.

How does CAD-CAM software benefit CNC machining?

CAM (Computer-Aided Manufacturing) software plays a crucial role in modern manufacturing by transforming design data into machine instructions. It automates the creation of toolpaths, optimizing processes like parts placement, cutting programation. This ensures precision, reduces human error, and enhances production efficiency. CAM software also enables the simulation of machining processes, helping to identify potential issues before actual manufacturing, saving time and resources.

What is the relationship between CAD/CAM software and nesting software?

CAM is widely used where high precision cutting and automation manufacturing are critical. Industries using CAM and nesting tools commonly work with materials such as steel, aluminum, wood, composites, plastics, and foam. These materials are optimized for cutting processes in sectors like manufacturing, aerospace, furniture production, and textiles.

What industries commonly use CAM software?

CAM (Computer-Aided Manufacturing) software is widely used in industries requiring precision and automation in manufacturing processes. Common applications include sheet metal industries, where components are cut, bent, or punched; shipyards, for fabricating large-scale parts like hulls and structural components; and the transportation sector, including automotive and aerospace, for producing complex parts such as engines, body panels, and aircraft components. Additionally, it is extensively utilized in the metalworking industry, where subcontractors manufacture custom metallurgical parts for their clients, ensuring precision and efficiency in tailored production.