Robotic Welding and OLP Software: The Solution to Welding Challenges

The welding market is undergoing significant upheaval worldwide, both in terms of human resources and technology. At Alma, we have been working on this subject for over 10 years. To better understand the trends in this industry and the solutions to assist metal fabrication companies, we interviewed an expert at Alma.

The Interviewed Expert

Fabien Arnoux is a Support Engineer specializing in robotic welding applications at Alma. He works closely with metal fabrication companies in France and around the world, offering guidance on how to effectively implement welding robots and helping them build their expertise in Offline Programming (OLP)

Use the video chapters to navigate quickly:

- Welding Market Trends

- Challenges Faced by Companies

- How Almacam Weld Addresses These Challenges

- Customer Case Study: Thievin

- Customer Case Study: Howden

- Innovations in Almacam Weld

What are the major trends in the welding market?

Two significant trends are reshaping the welding industry:

-

Increasing Demand and Worker Shortages

While the global demand for welding professionals continues to grow, there is a widespread shortage of skilled operators. For instance, in the United States, the American Welding Society projected a shortfall of 400,000 welders this year. -

Rise of Industrial Automation

Concurrently, with the advent of Industry 4.0, the market is becoming increasingly automated. The density of industrial robots worldwide has doubled over the past six years and continues to rise.

What challenges are companies facing?

Welding companies are encountering four major issues:

-

Severe recruitment difficulties,

-

Significant time losses due to robot programming,

-

Challenges in welding small production runs, large parts, and complex assemblies,

-

Difficulty in ensuring consistent quality.

How has Almacam Weld resolved these issues for your clients, and what are the results ?

Robotic welding is an automated assembly process that uses robots programmed to perform precise and repetitive welds.

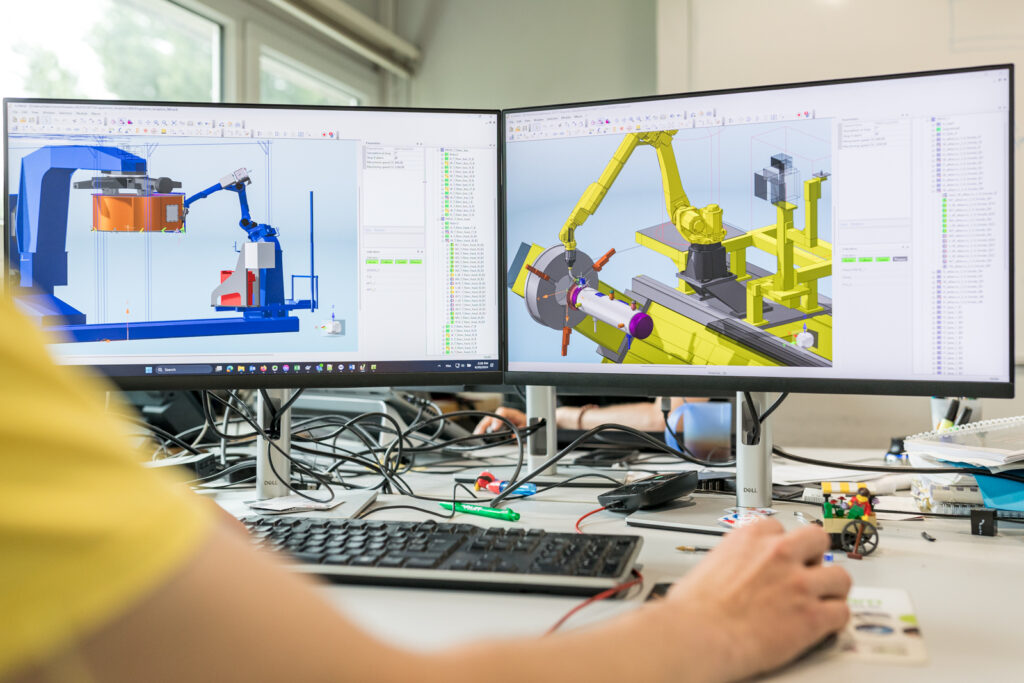

Almacam Weld is a Smart and Automated Offline Programming (OLP) software designed to master complex robotic welding. We collaborate with both industrial welding companies and integrators of robotic cells.

With Almacam Weld, metal fabrication companies have achieved simplicity and greater efficiency in programming their robots, as well as improved welding reliability.

A factory director once summarized it perfectly: Our robots are incredibly efficient tools that do what we tell them. The intelligence has to come from the program. At Alma, that’s precisely our expertise: the intelligence behind the program—that’s Almacam Weld.

Thanks to Almacam Weld, our industrial clients have succeeded in:

-

Managing their entire fleet of welding robots, regardless of brand—whether ABB, IGM, Closs, Kuka, Staubli, Yaskawa, OTC Daihen, Kawasaki, Hyundai, or Fanuc, for example,

-

Saving significant time since programming is done offline, meaning their robots remain operational,

-

Boosting team productivity through hidden time programming (maximizing robot productive time and minimizing programming costs),

-

Achieving higher weld quality by automating tasks that are correctly calibrated beforehand.

For integrators of robotic cells, offering Almacam Weld enables their clients to harness the full potential of their robot cells. They deliver a turnkey solution that saves clients considerable time.

We adapt to the equipment provided by integrators and their partners, leveraging our development capabilities to interface auxiliary equipment with robots, such as relocation tools (cameras, probes) or articulated tooling.

Almacam Weld is a compelling solution for convincing clients who haven’t yet transitioned to robotics and are still using manual programming.

What makes Almacam Weld particularly innovative?

Among the innovations that clients particularly appreciate:

-

Complete simulation of the entire cell ensures feasibility during design and production.

-

Easy creation and automation of importing assembly trajectories.

-

Integration and reproducibility of welding parameters, such as torch angles and stick out.

-

Automatic search for robot trajectories that avoid collisions.

-

Automatic transfer of welding programs for identical or similar parts, significantly reducing programming time.

-

Automatic recalibration of trajectories using wire and nozzle probing, seam tracking, cameras, or laser sensors.

-

Synchronization of multiple robots and positioners.

However, I also recommend looking beyond the software’s capabilities and considering the support that comes with it. This is a key success factor in OLP. At Alma, our team works very closely with clients. We know our clients, understand their processes because we’ve visited their workshops, and guide them on how to improve their OLP workflows. There is a genuine mutual trust.