An extremely effective CAD/CAM software for on-demand production of numerous parts requiring punching-nibbling.

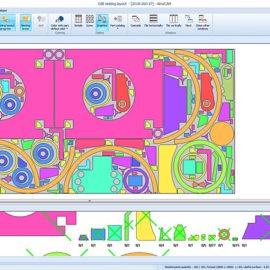

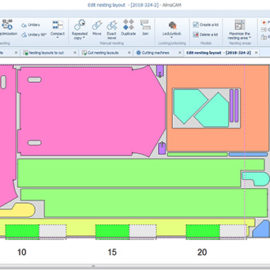

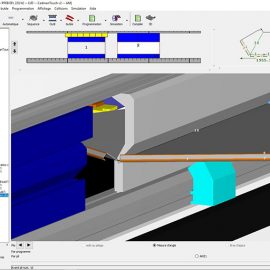

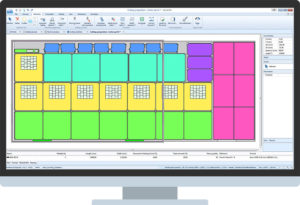

Almacam Punch’s added value lies above all in the software’s powerful automation features at every stage of programming: tool allocation, machining sequence, nesting, part evacuation, etc.

The built-in nesting module reduces material consumption while adapting perfectly to punching constraints (tools, work areas, clamps, etc.) Almacam Punch manages all the loading/unloading peripherals. The software combines perfectly with the other products in the Almacam range to control combined laser/punching machines and cutting machines that follow profiles.

Xavier Charriton

Director of Ticem

“We decided to opt for the Alma solution, which was perfectly aligned with our strategy consisting in systematically optimizing flows, reducing manufacturing cycles and maximizing material gains. For a recent project, thanks to Alma’s nesting, the material requirement was reduced from 63 sheets to 53 compared to the previous software, a net material gain of 11%.”

The punching-nibbling machines we drive

Get Almacam Punch

Almacam Punch software can be installed on-premise, on your servers. It is available as a perpetual license or as a flexible subscription with Almacam Pass.

More information

Additional information

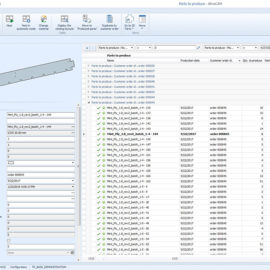

The Almacam environment provides completely secure and traceable management of manufacturing data. Adopting the “Industry 4.0” approach, Almacam interfaces seamlessly with the company’s information system and can be easily connected to Production Management and ERP software amongst others. Almacam provides workshop management tools, and a production statistics module.