Improve production efficiency with an automated solution to program your tube and profile cutting machines

Subcontractors and sheet metal companies can face significant challenges in optimizing tube (and pipe) and profile (and beam) cutting. Complex geometries, material waste, and inefficiencies of manual operations hinder productivity, increasing costs and complicating tight production schedules.

Almacam Tube addresses these challenges by automating the cutting process, optimizing material usage with advanced nesting algorithms, and ensuring precise machining of complex geometries.

Powerful 3D CAD/CAM features for designing, nesting and cutting tubes and beams

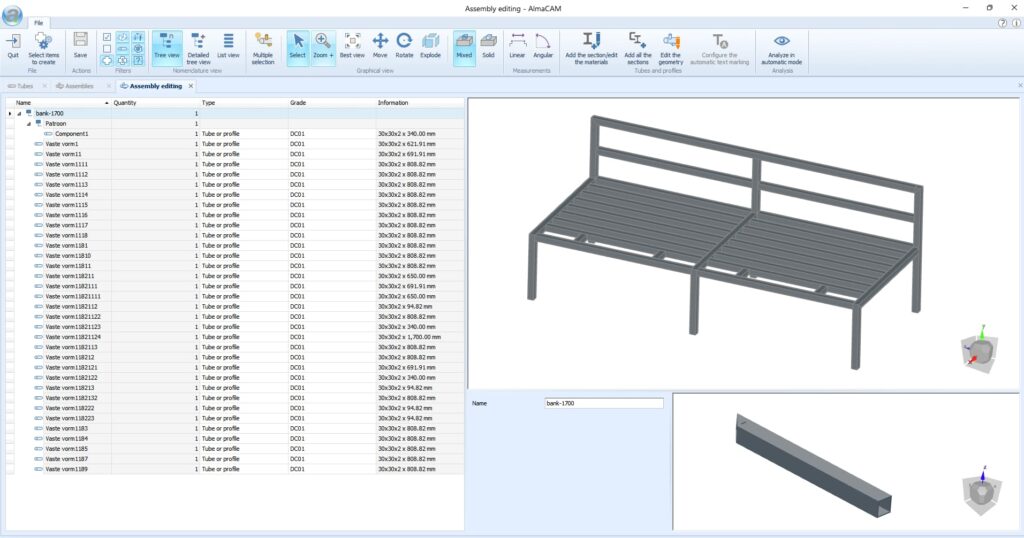

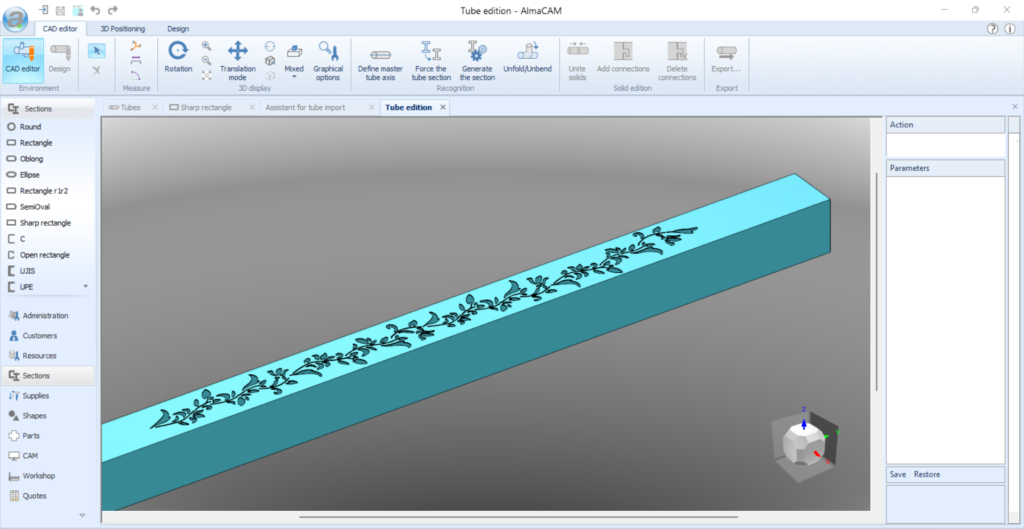

Design of tubes and import of assemblies

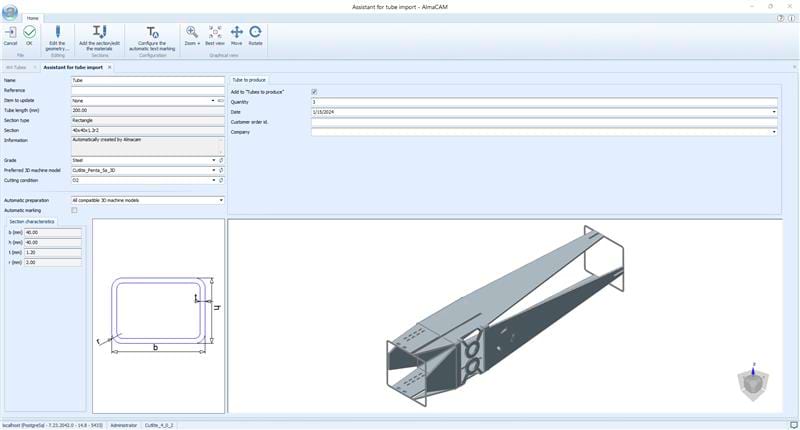

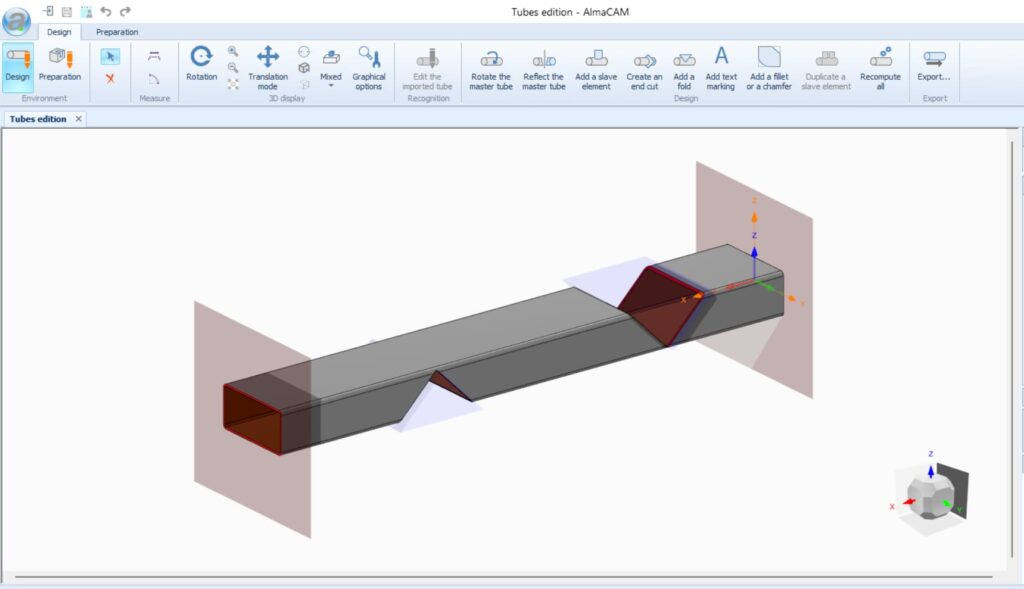

- 3D design of tubes and profiles, supporting any section type, customizable shapes (sections, holes) and specific end cuts

- Import of 3D parts and assemblies from Parasolid, STEP, IGES, SAT/ACIS formats, Catia V4/V5, PTC Creo/ProENGINEER, Inventor, Solid Edge, SOLIDWORKS, IFC, DSTV

- Automatic recognition of pipe sections during CAD import

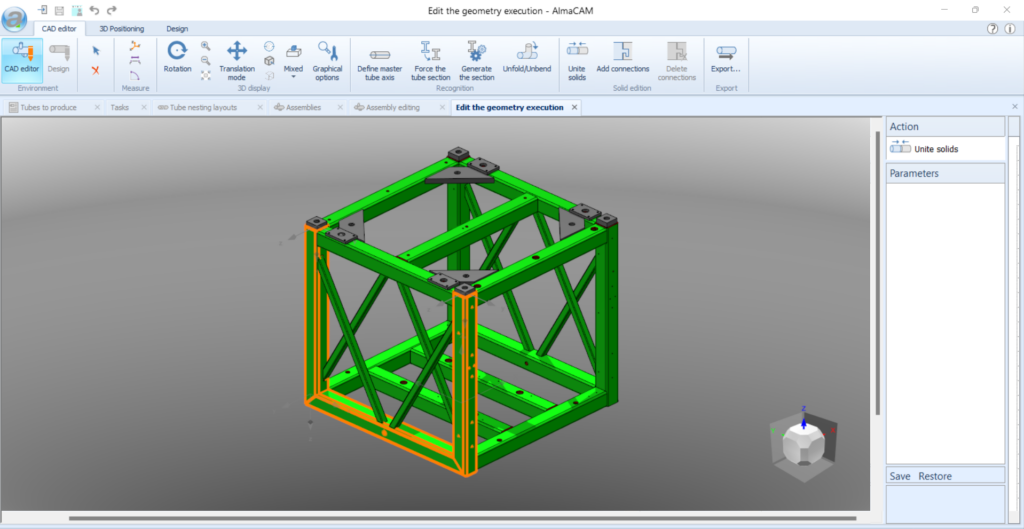

- Capability to modify the geometry of imported CAD parts and add connections as notches between parts of an assembly with Assembly2cam

- Possibility to unfold or unbend an imported CAD part

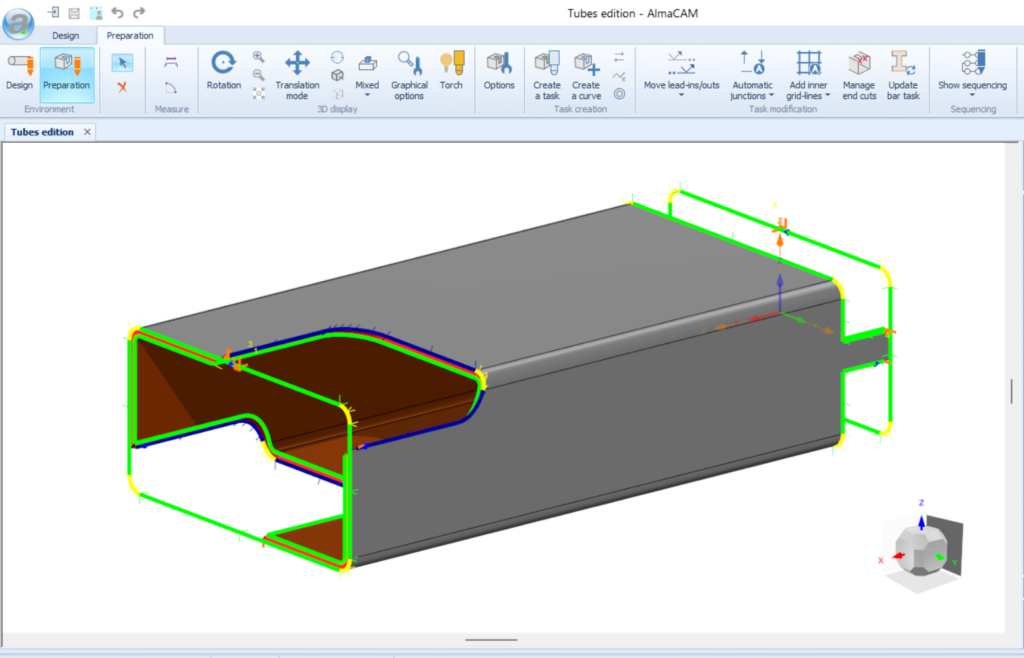

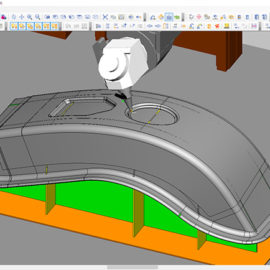

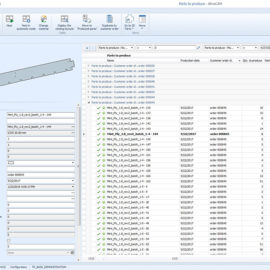

Automated cutting preparation

- Automated preparation with optimized cutting trajectories, sequences and most suited cutting conditions

- Feature for automatic defining trajectories of complexx extremity cuts

- Adaptation of trajectories based on the cutting machine capabilities

- Support of machines combining laser cutting and mechanical processes (drilling, milling, tapping, etc.) with automatic tool allocation for mechanical operations

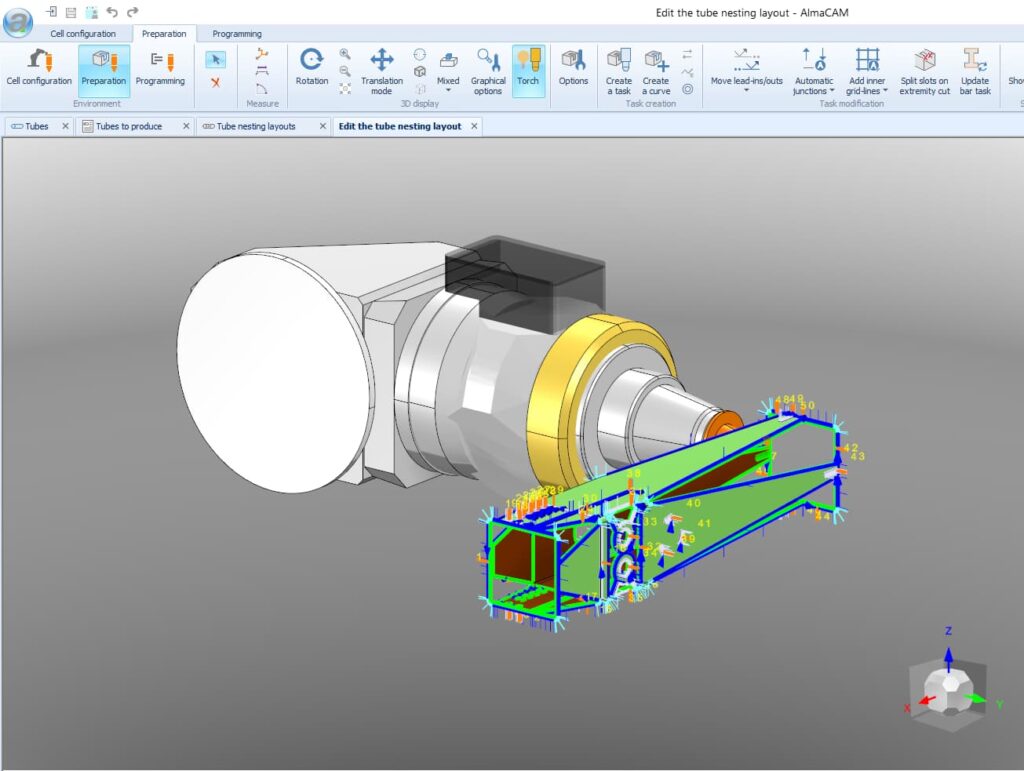

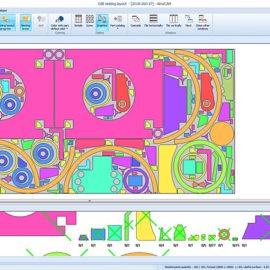

Optimized nesting of tubes & profiles

For over 45 years, Alma has been a leader in developing advanced nesting algorithms, ensuring customers get the most optimized sheet metal part layouts available on the market.

- Automatic nesting of any tube and profiles sections

- Nesting in offcuts

- Management of common cuts

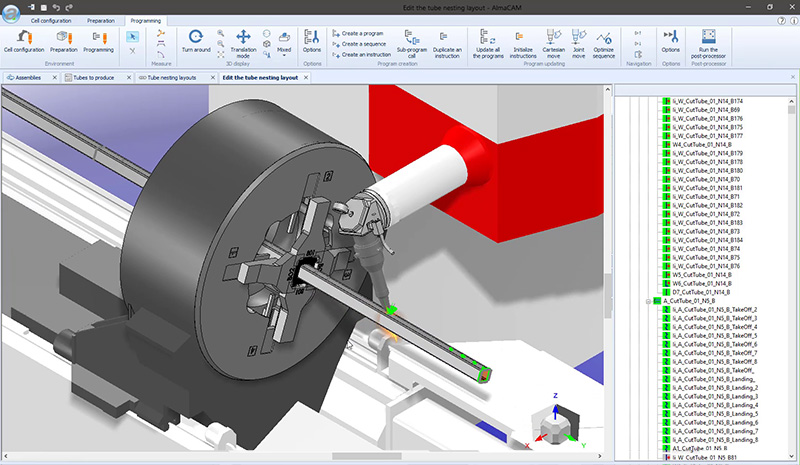

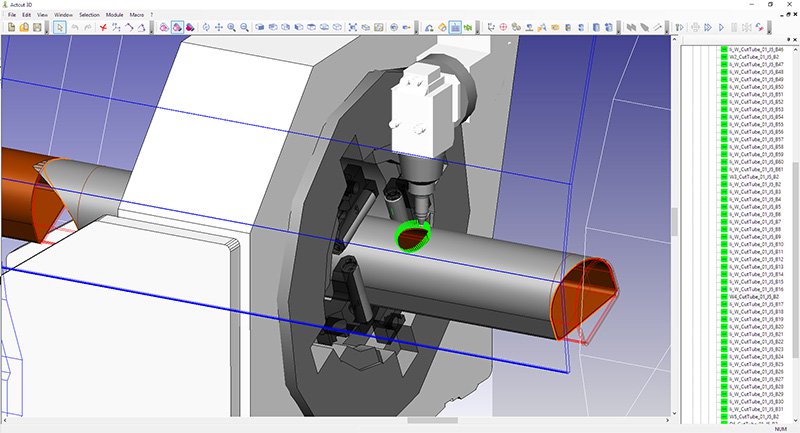

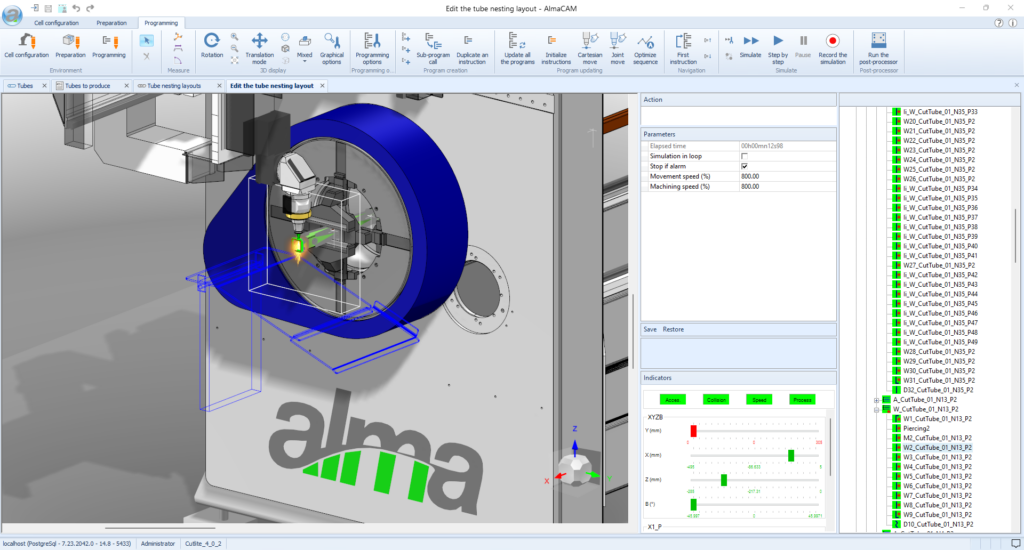

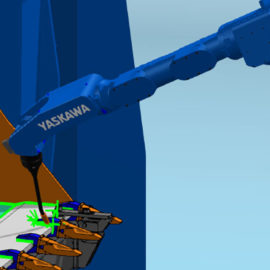

Real-world simulation of tube cutting machines

- Automatic creation of the cutting program

- Realistic simulation and control functions with visual anomaly indicators

- Assessment of cutting feasibility according to machine characteristics (axis ranges, speeds and accelerations) with automatic detection of potential collisions

- Simulations of multi-mandrel machines

- Management of sensing operations (e.g., hole centering, tube twisting)

- Generation of NC programs using a machine-specific postprocessor and generation of a workshop document.

Support of all brands of tube cutting machines

Almacam Tube CAD/CAM software is able to interact with any kind of tubes and beam cutting system (3, 4 or 5 axis machines with one or more rotative axes, robotized cells for cutting tubes).

Some tube cutting machine brands we drive

License or Subscription, you choose

Almacam Tube is installed on-premise with a perpetual license or with a flexible subscription with Almacam Pass.