Almacam: ERP/Production Management Systems integration

Almacam integrates natively into the customer’s information system, delivering seamless data exchange

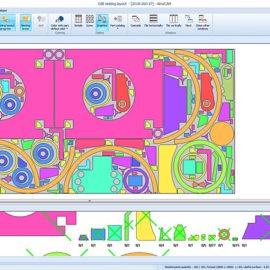

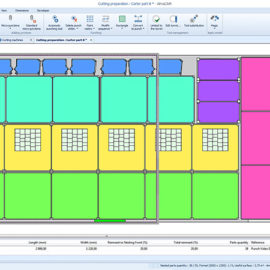

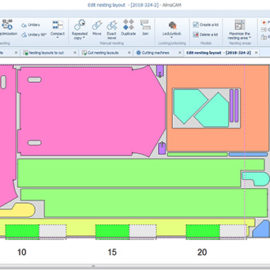

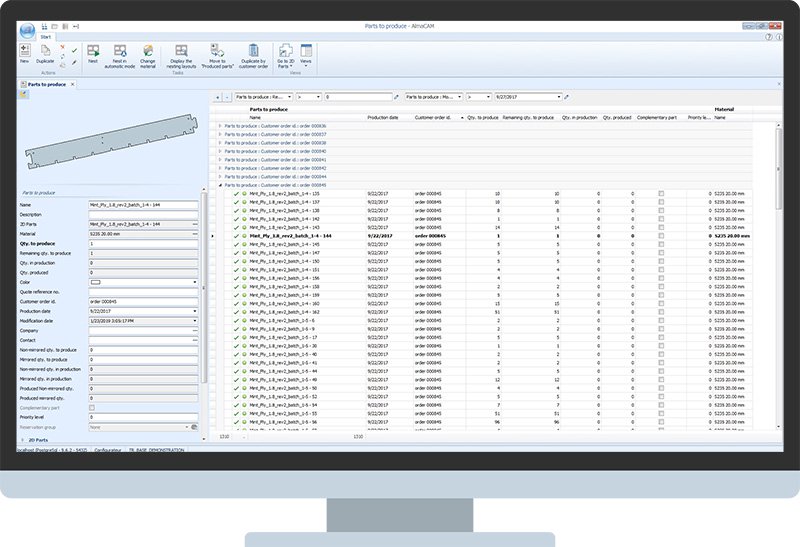

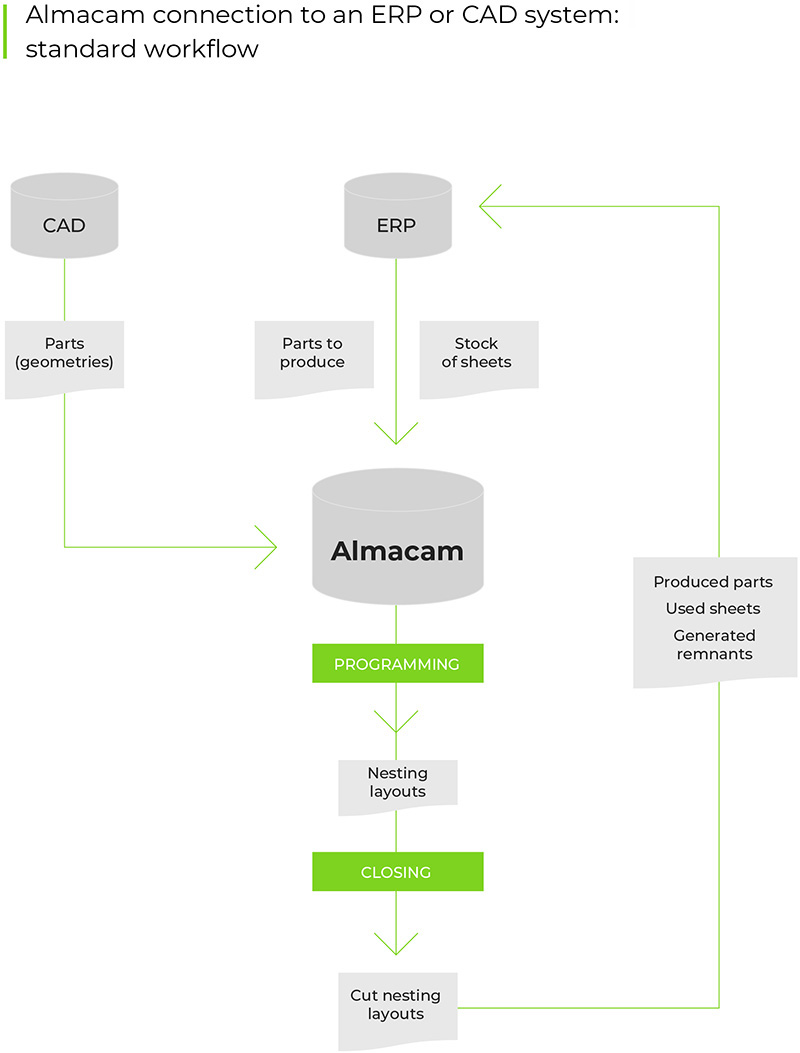

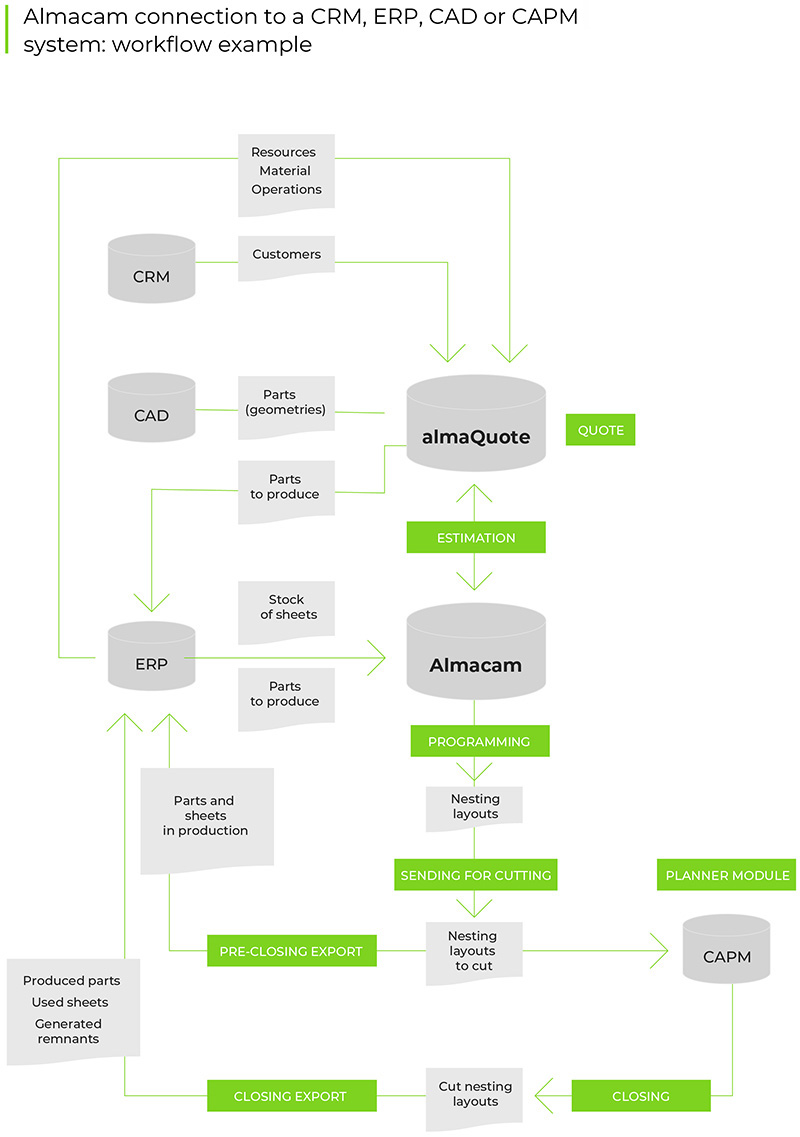

The programming software is an essential link in the digital chain, making it possible to manage machines and optimize production in the workshop on the basis of information supplied by ERP, Production Management Systems and CAD.

It enables Alma’s CAD/CAM software to communicate perfectly with the company’s information systems: leverage of data to start manufacturing or to manage inventory (ERP, Production Management, metal sheet quotes), retrieval of technological information concerning the parts to produce (CAD, GDT), transfer of production information (MES), etc.

This integration requirement was taken into account when designing the architecture of our products. Almacam is designed to be an open environment where exchanges with other information systems are managed natively with an adaptive approach. Data imports/exports are an integral part of the system and can be adapted to the specific needs and characteristics of our customers.

Almacam: a natively adapted environment to integrate into any information system

Complete integration into an automated process

Completely secure data exchange

Limitless adaptability to the customer’s organization

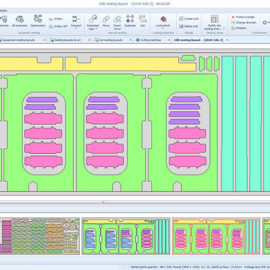

Yann Crépeau – Chantiers de l’Atlantique shipyards

“In parallel to setting up our new ERP, we wanted to rationalize our nesting processes and harmonize our CAM tools. Using Alma as a single Cutting CAAM enabled us to achieve this objective. This solution has several advantages: simplification of data exchange between the ERP and Alma, more versatility from operators, possibility to transfer manufacturing orders from one workshop to another, facilitated support and maintenance.”