Labor shortages, rising costs, and complex demands make automation essential. Traditional robot programming can slow you down. Modern Offline Robot Programming changes that. Discover how to simplify programming for complex robots.

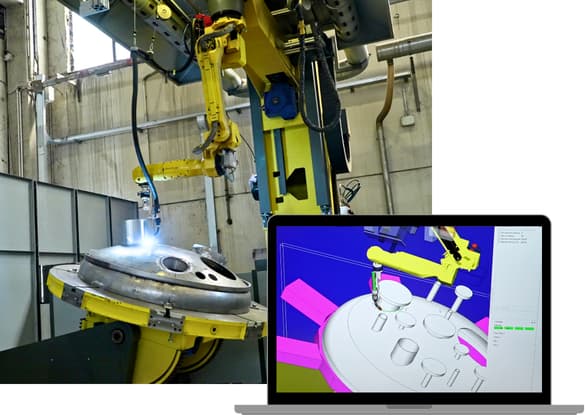

Building on its CAD/CAM expertise, Alma has developed robotic solutions dedicated to manufacturers and robotic cell integrators, to simplify their day-to-day work. Among those, Almacam Weld is the flagship software to tackle welders’ toughest challenges.

What is Offline Robot Programming (OLP)?

Offline Robot Programming (OLP) is a new way to program robotic systems without interrupting production. Instead of programming robots manually on the shop floor, OLP uses advanced software to create and optimize robot programs in a virtual environment. This approach is faster, more efficient, and eliminates downtime.

How does OLP work?

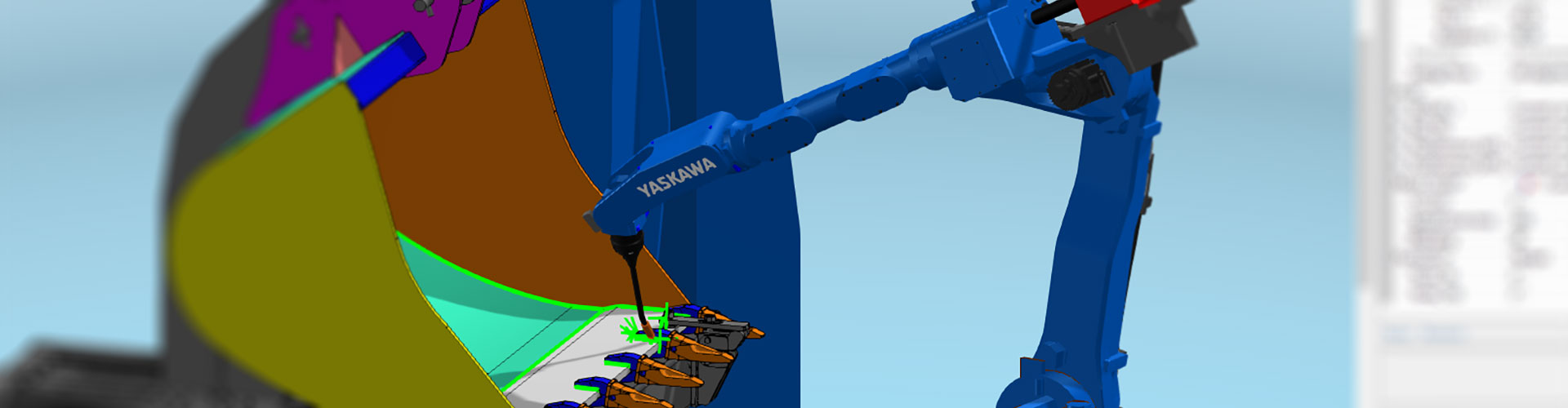

OLP software creates a like a digital twin of your welding robot and its environment. You can simulate, test, and refine weld paths, torch angles, and movements directly in the software. Once finalized, the program is sent to the robot, ready to execute with precision.

Why choose an OLP software for Robotic Welding?

In today’s competitive market, robotic welding systems are essential for manufacturers and integrators. Traditional manual programming is slow, error-prone, and can require advanced expertise. OLP solves these challenges by automating and streamlining the process.

Investing in OLP software for your welding robots gives you a competitive asset. You will maximize the investment of your robotic systems and provide better deliveries to your customers.