Searching to increase workshop productivity? Wasting time programming your robots? Struggling to find qualified welders? Controlling a robot can be done without coding expertise and without stopping production.

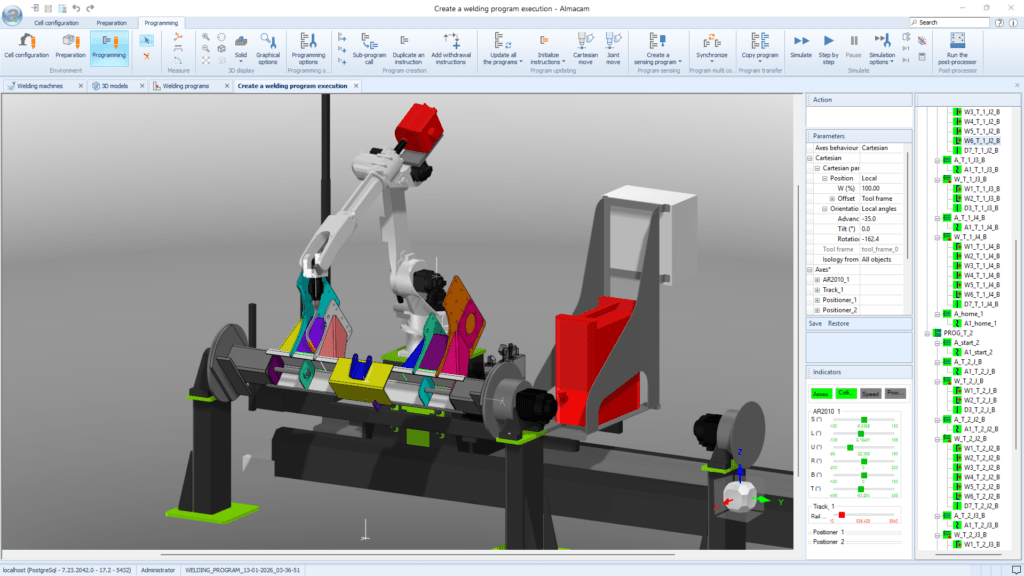

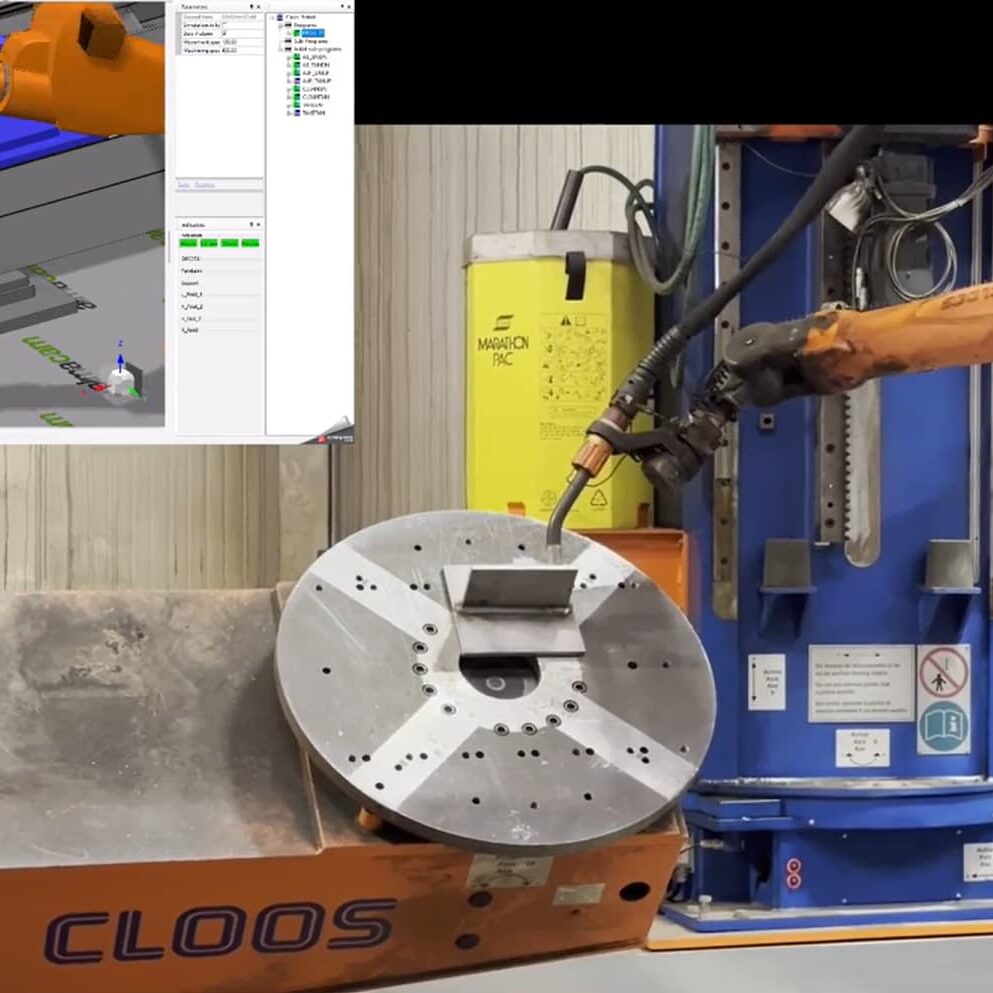

Designed specifically for welders, Almacam Weld helps manufacturers and integrators save time and money. With Almacam Weld Offline Programming (OLP) software, users of all experience levels can now program quickly and effortlessly arc-welding robots, even the most complex tasks.

Almacam Weld supports the most common robots

“With Alma’s OLP software, we estimate that we reduce the manufacturing time for parts by 2.5 to 4 times compared to manual welding.”

C. Duret, Maintenance Manager, THIEVIN

Smart & Automated Features for Efficient Robotic Welding

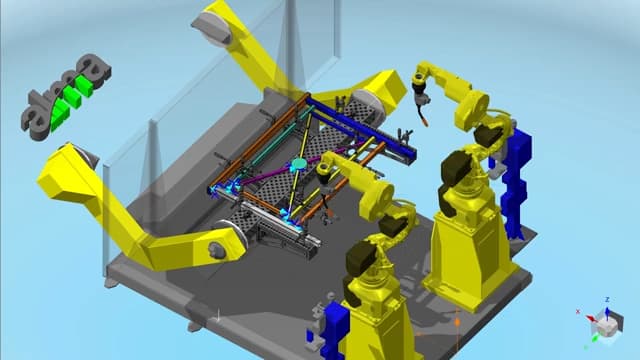

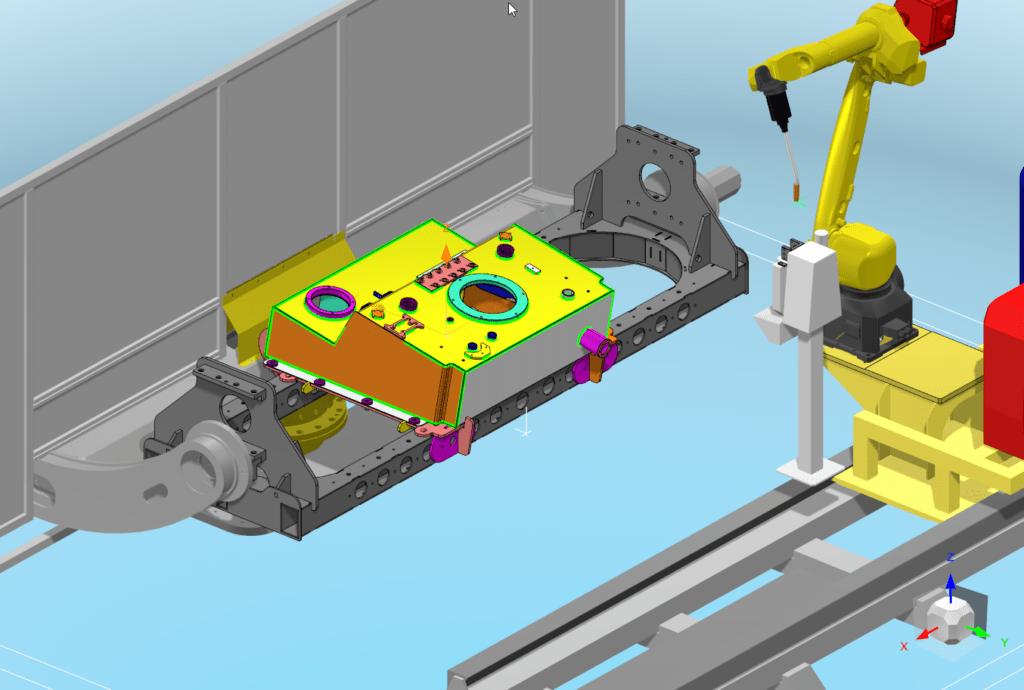

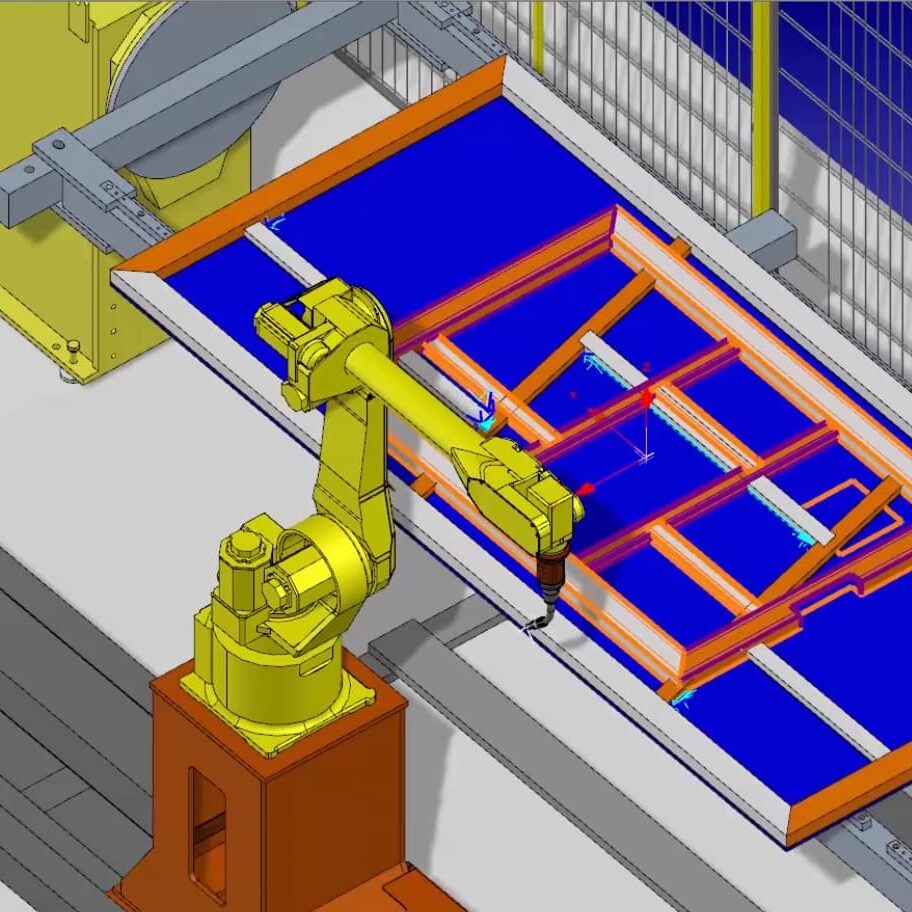

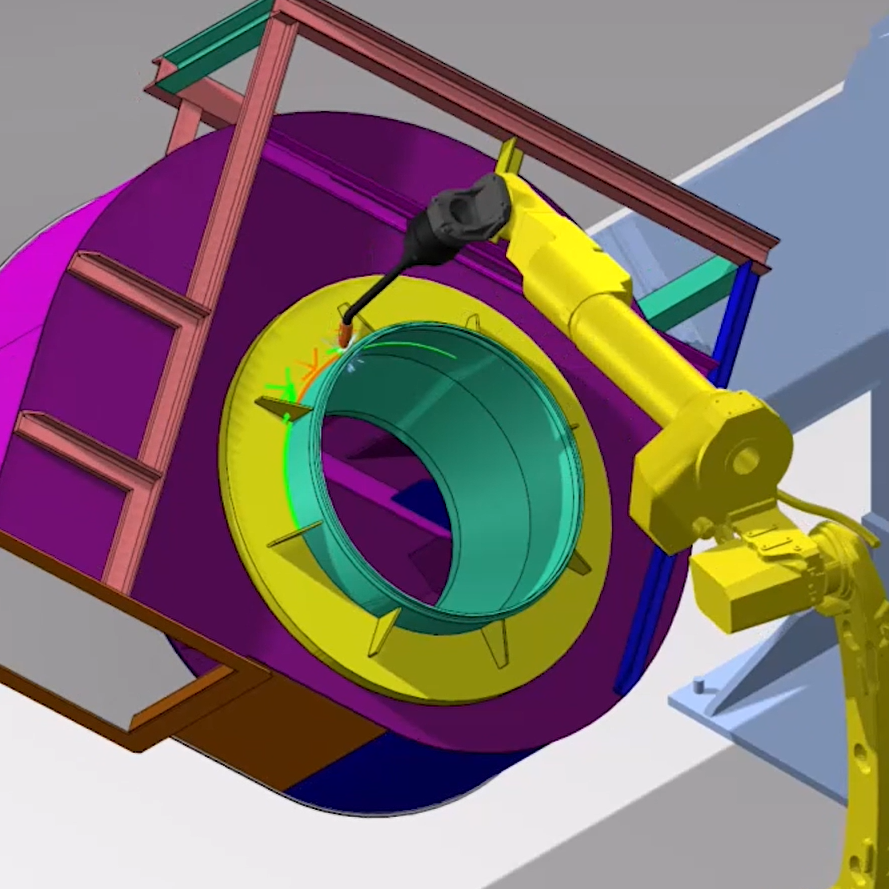

- Thorough 3D realistic simulation of the cell, which guarantees feasibility in design and production.

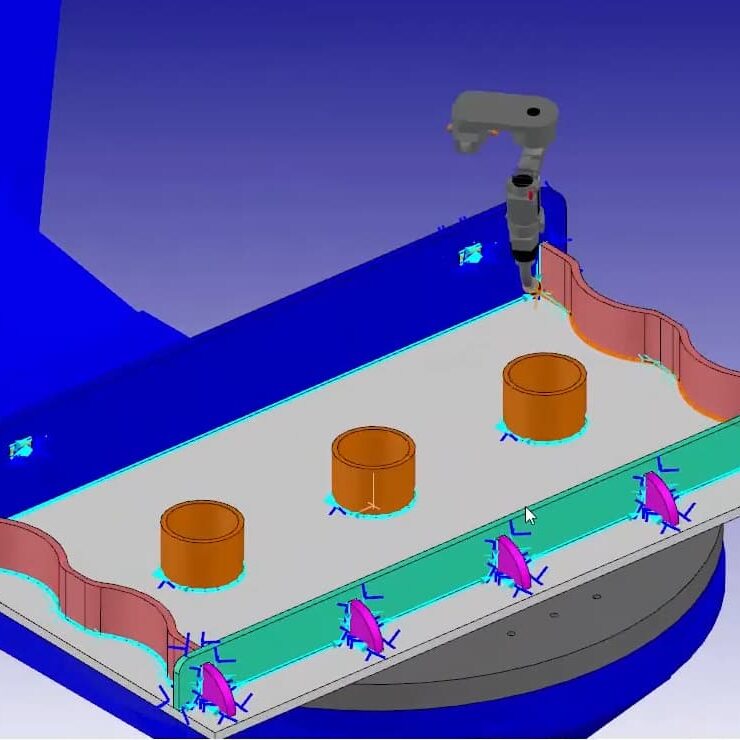

- Easy creation and automation of the import of welding trajectories.

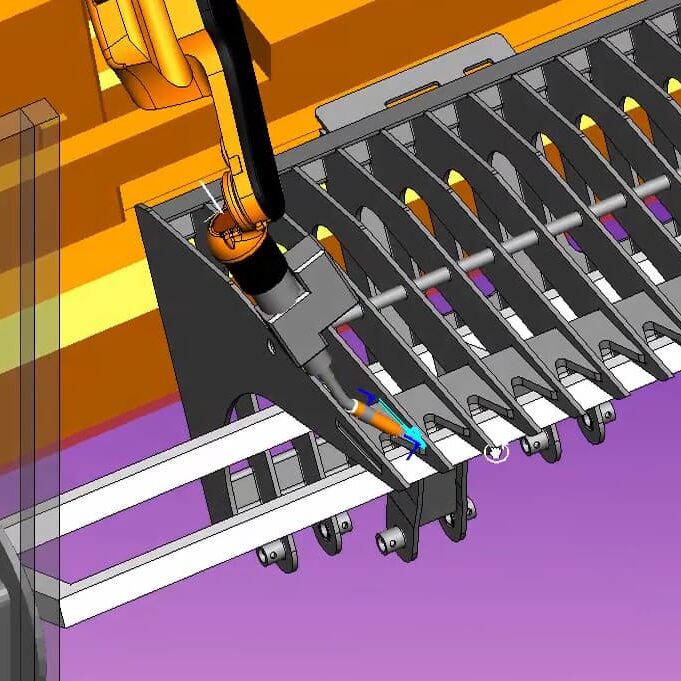

- Integration and replicability of welding parameters such as electrical parameters, but also stick-out and torch angles.

- Automatic search of robot trajectories for collision avoidance.

- Automatic program transfer to identical or similar parts, which significantly reduces programming time.

- Automatic trajectory recalibration through sensing with wires, nozzles, cameras, or laser.

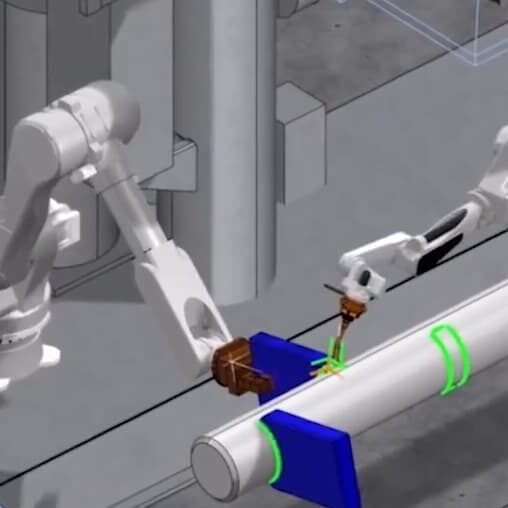

- Synchronization of several robots and positioners.

Robotic welding is a journey. We’ll be there at every step

At Alma and in collaboration with our partners, we deliver more than software—we deliver solutions. We transform challenges into opportunities to boost your workshop’s productivity.

Are you a Robotic Integrator ?

Learn how Almacam Weld brings value to robot solutions.