Alma has many years of experience with plasma cutting, a technology that is particularly widespread in industries that use half-thickness sheet metal, especially ship-building. Plasma cutting was the starting point for several innovations in programming methods devised by Alma: continuous cutting without lead-ins/outs, bevel programming, etc. In addition to flat cutting, Alma software for 3D cutting or beveled cutting also comprise plasma cutting processes.

The Plasma cutting technological process

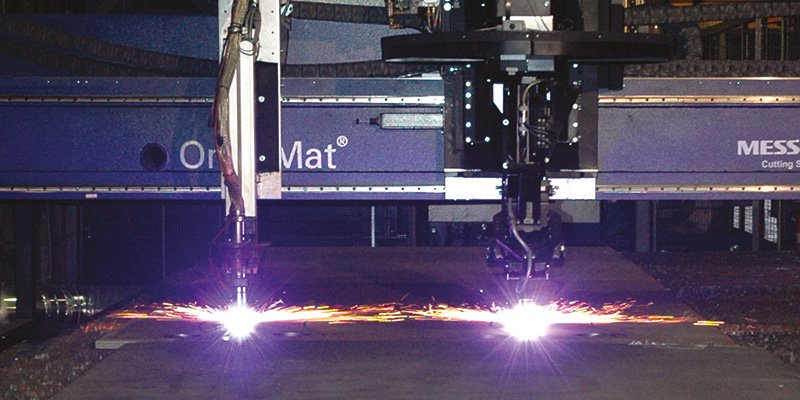

The plasma cutting process consists in cutting by localized fusion using an electric arc. The energy is concentrated in the form of a jet of ionized gas – the plasma – channeled at very high speed onto a precise point on the metal surface of the part. The thermal energy of the arc (up to 20,000°C) and kinetic energy of the jet melt the metal at the point of impact and blow the molten metal out of the cut area.

This process is mainly used for medium thickness sheets (10 to 30 mm) but can cut any electro-conductive material with a thickness between 0.5 mm and 160 mm. The cutting precision is roughly 0.2 mm, making it possible to produce bevels. The main advantages of this process used very widely in the ship-building industry are: minimized deformation, high cutting speed for small to medium thickness sheets, possibility of using several torches, minimal burring on cut materials, etc.

Advantages of Almacam Cut for plasma cutting

The performance of Almacam Cut in plasma cutting are due in particular to its capacity to satisfy technological requirements, to support specific machines and processes (particularly in the ship-building industry), and also its capacity to function entirely automatically.

Significant material savings

- Significant reduction of loss rates thanks to automatic nesting performance, since there is a choice of several available strategies.

- Optimized use of remnant sheets or off-cuts of any shape.

Minimized programming times

- Possibility to operate in full automatic mode.

- Management of repetitive nesting and sub-nesting (kits) enabling future re-use of optimized programs.

- Possibility to modify the profile characteristics (lead-ins/outs, bevels, etc.); which avoids modifying the geometry.

Savings on consumables

- Limited number of sheet drillings thanks to several cutting methods: continuous cutting (bridges), common cut, etc.

Optimized time cycles and complete safety

- Optimized computation of the tool paths.

- Reduction of cycle times thanks to different methods making it possible to avoid drilling by profile: bridges between parts, common cut.

- Automatic positioning of lead-ins/outs to avoid collisions with parts already cut.

- Height control to allow straight or beveled cutting.

Complete mastering of the technological process and complex machines

- Ability to control programmable beveling heads while automatically preparing the program: pass sequence and offsets computation, automatic generation of the reconfiguration loops or lead-ins/outs, generation of an overall profile to take into account the maximum bulk of the part in the nesting, allocation of cutting conditions according to the angle.

- Support of all processes that can be combined with plasma cutting; drilling, sand-blasting, marking systems (alphanumeric marking by ink jet or plasma, etc.)

- Interaction with combined machines (plasma and drilling).

- Support of complex machines: machines to machine flat panels in ship-building, machines allow symmetrical cutting, marking of bottom side, pseudo parallel cutting, etc.

An approach that contributes to improving the quality of manufactured parts

- Heat deformation taken into account thanks to several automatic or semi-automatic functions: heat distribution over the sheet with specific cutting sequence, etc.

- Automatic lead-ins/outs (position, type, length and angle) according to the material and thickness, and automatic correction of false lead-ins/outs.

- Overlapping at the end of cutting to avoid burrs.

- Perfect parameter management according to cutting conditions used (gas, amperage, nozzle).

- Mastery of cutting of circular holes.

Methods to facilitate handling in the workshop

- Hierarchical nesting using priority groups to easily sort the parts during evacuation.

- Skeleton cutting to facilitate evacuation of the remnant.

- Use of plate straps to keep certain inner profiles attached and avoid deformation problems when handling parts.