The nesting software to program your combined laser/punching or plasma/drilling machines with maximum automation and flexibility.

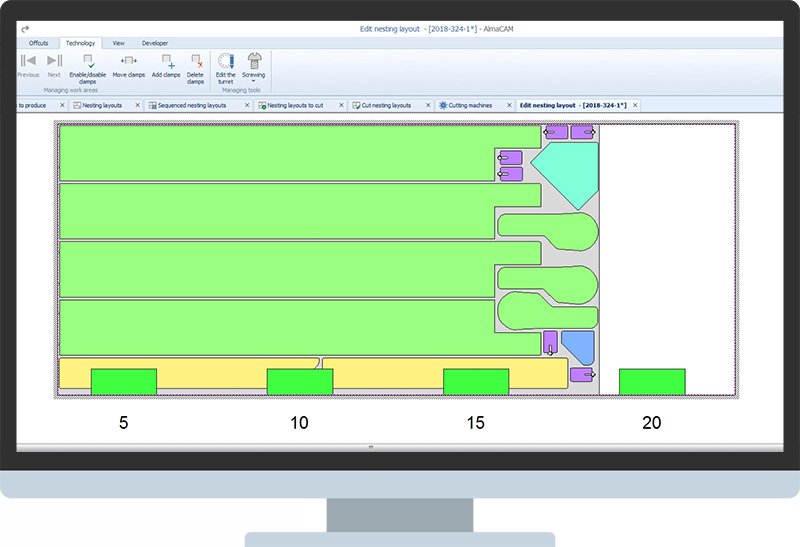

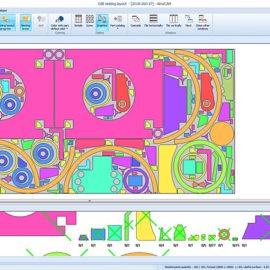

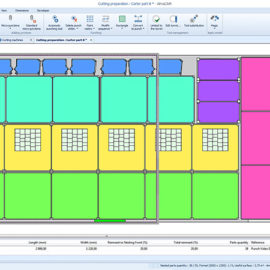

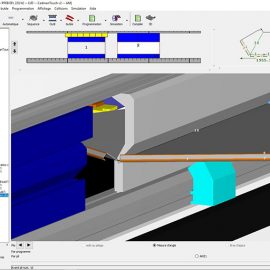

The Almacam Combi CAD/CAM software supports all brands of combined laser/punching and plasma/drilling machines. The specificities of each technology are taken into account at every stage of programming: part preparation, nesting, machining sequence, tool trajectories and generation of the NC code.

The software powerful automation features (tool allocation, machining sequence, nesting, part evacuation, management of loading/unloading peripherals, etc.) make Almacam Combi a highly productive solution for on-demand production of numerous and varied parts. Thanks to its exclusive nesting algorithms that fit any type of cutting need, Almacam Combi significantly reduces material loss rates.

The machine brands we drive

Get Almacam Combi

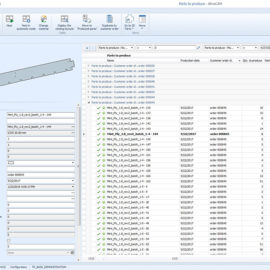

Almacam Combi provides completely secure and traceable data management in a collaborative environment. Adopting the “Industry 4.0” approach, Almacam interfaces seamlessly with the company’s information system and can easily be connected to Production Management and ERP software amongst others. Almacam provides workshop management tools, and a production statistics module, for complete integration into the “ERP/Production Management/Workshop” digital sequence.

Almacam Combi provides completely secure and traceable data management in a collaborative environment. Adopting the “Industry 4.0” approach, Almacam interfaces seamlessly with the company’s information system and can easily be connected to Production Management and ERP software amongst others.