Almacam 4.1.1: Our green roadmap brings even greater savings, automation and sustainability

Published on 05/09/2025

As a leading CAD/CAM and nesting software provider, Alma believes it has a key role to play in helping sheet metal working companies reduce their environmental footprint. Leveraging our long-standing expertise in creating solutions that empower metal companies, we are taking our commitment even further with our green roadmap, optimizing material and energy usage and minimizing scrap. The new version of Almacam embodies this commitment. Read on.

Green Roadmap

Optimized Nesting for material savings and sustainability

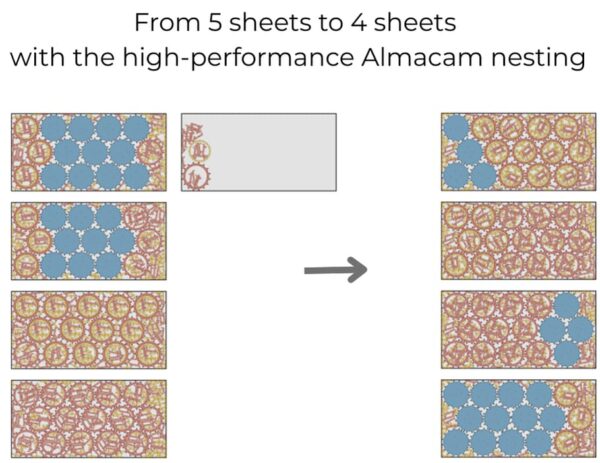

Alma continues to push the limits of parts’optimization. With this new version, Almacam’s nesting performance has been significantly improved, delivering an average 0.65% material gain compared to previous versions.

In practical terms, this means fewer sheets are needed for the same production. For example, the set of parts shown below now requires only 4 sheets instead of 5.

Benefit for users: direct material savings, higher efficiency, and a lower environmental footprint.

This improvement is a concrete step in Alma’s green roadmap: by reducing material consumption, we help our customers minimize waste and use resources more responsibly — another contribution toward a more sustainable manufacturing process.

Turning scrapped parts into reusable offcuts

A new feature now allows users to keep sheet metal scrapped parts as reusable offcuts instead of discarding them. This reduces unnecessary waste and gives a second life to material that can be used in future jobs.

Once again, this means lower material costs and smarter resource utilization

Almacam Tube

Almacam is already a leader in automatic preparation of tubes and profiles. With this release, we’re taking it one step further extending our strong automatic preparation capabilities to a new family of profiles and improving the creation of inner grids.

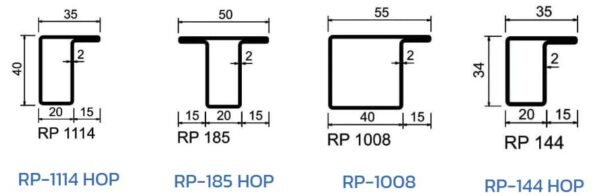

Automatic LTZ profile recognition

LTZ profiles are special hollow window frame profiles combining L, T, and Z-shaped elements.

Until now, LTZ profiles had to be imported as free profiles and manually adjusted in Almacam — a repetitive and time-consuming task.

With the new dedicated LTZ section type, Almacam now automatically recognizes LTZ geometries and assigns the right parameters instantly.

- No more manual adjustments

- Faster preparation

- Greater reliability

Result: Users save valuable time and gain efficiency in their daily work, allowing them to focus on production rather than preparation.

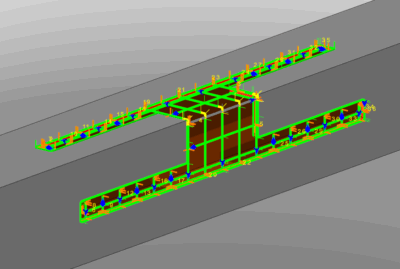

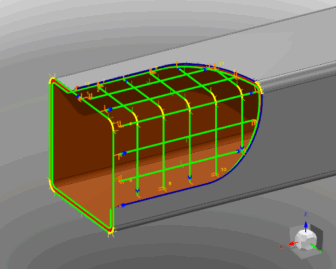

Improved Inner grid function

In Almacam Tube, the “Add inner grid” function enables users to create cutting operations inside holes to break scraps into smaller pieces, making it easier to remove.

Up to now, this feature was limited to flat faces or cylindrical faces on round tubes, which meant it could not be applied to curves spanning several faces.

Now, with the 4.1.1, users can now apply the “inner grid function” to closed curves spanning several faces.

New APIs for quotations

A new set of APIs is now available to streamline the creation of quotation, making ERP integrations smoother than ever.

These APIs allow users to automatically generate the structure of a quote and import data directly from CSV or XML files, including:

- Parts from DXF files

- Tubes from STEP files

- Operations

- Supplies

- Hierarchy to organize and structure the quote

Benefit for users: less manual data entry, faster quote preparation, and seamless integration with ERP systems — saving time and reducing errors.