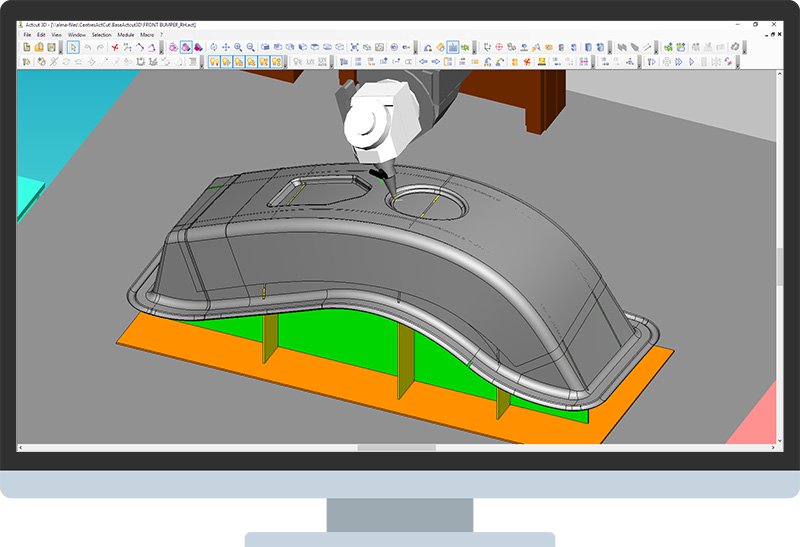

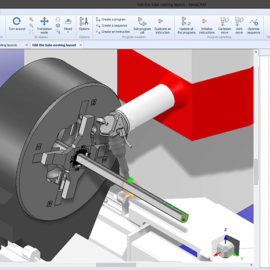

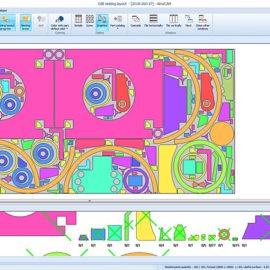

A CAD/CAM programming software for all your 5-axis cutting machines and cutting robots

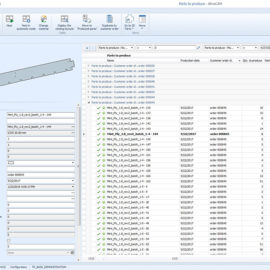

With its simple and intuitive user interface, the Almacam Space Cut CAD/CAM software is dedicated to the programming of any type of 3D-cutting machine (laser, plasma, water jet) regardless of the number of axes. Almacam Space Cut combines automation and simplicity of use. Providing support for advanced manufacturing functions, Almacam Space Cut adapts to every kind of situation, enabling you to cut complex parts.

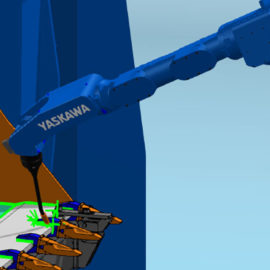

3D cutting machine brands we drive