To write down this article, we have interviewed our team of algorithmic engineers and one of our expert in shipbuilding.

In the complex and competitive world of shipbuilding, maximizing efficiency and minimizing waste are not just goals—they are must-have for success. Nesting, the process of arranging multiple parts within a given space to minimize waste, is a key strategy that can make a significant difference. This article explores how effective nesting strategies can transform shipyard operations by cutting costs, saving time, and promoting sustainability. By understanding the difference between efficient and poor nesting, and the impact this has on the bottom line and the environment, shipyards can stay ahead in a demanding industry. Read on.

Differences between a Bad and an Efficient Nesting

The nesting feature is the cornerstorne of a good CAM software and relies on algorithms. The difference between a bad and efficient nesting strategy lies in the sophistication of the algorithms and the ongoing refinement they undergo. Efficient nesting utilizes powerful algorithms that can analyze and optimize the layout of parts on a material sheet.

Manual versus Automatic Nesting

Automatic nesting in shipyards offers significant advantages over manual placement. It optimizes material usage and speeds up production times. Manual placement, on the other hand, is time-consuming, prone to human errors, and often leads to inefficient material use. The automated nesting in Almacam saves time by removing the need for manually arranging parts on a sheet. Almacam evaluates the geometry and creates the smartest placement automatically thanks to the most sophisticated automatic nesting functions: rotation of parts around any angle, management of prohibited part positions and nesting priorities, compaction of existing nestings, optimization of the spacing between parts in an existing nesting, nesting of parts in n-level recesses, multi-format nesting, management of multiple nestings, and more.

Simple versus Complex Geometry

Unlike basic methods, sophisticated nesting systems can handle complex geometries and diverse part sizes. For example, Almacam algorithms have been designed specifically to manage parts for shipyards, with complex geometries, lots of single parts and few repetitive parts. Standard nesting system are not able to deal with these requirements.

Outdated versus Continuously Improved Algorithms

Having been strengthened over the past 40 years, Almacam’s nesting algorithms are extremely powerful. Our Premium algorithms are continuously improved by a dedicated team of engineers and mathematicians who work to enhance their precision and efficiency. In contrast, bad nesting might rely on outdated or less sophisticated algorithms that fail to optimize material usage effectively.

With Almacam, the plate nesting work becomes faster, the use of material is more efficient. So the work can be completed more quickly.

Comparing Nesting for a Shipbuilding Use Case

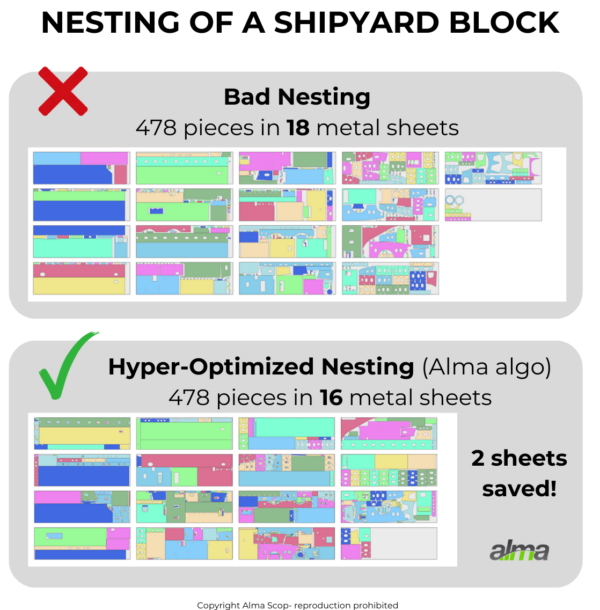

To show you concretely the difference between an inefficient and a powerful nesting in a CAD-CAM software for shipbuilding, our team of algorithmic engineers have made simulations with two opposite situations for the placement of 478 parts on metal sheets for a shipyard block. This is a real simulation, with real-world parts of a shipbuilding project.

- The first simulation with a bad nesting requires 18 sheets,

- The second simulation with an hyper-optimized nesting (made possible in Almacam) requires 16 sheets.

As you can see the savings of material raw is huge: 2 plates for one single block, i.e. about 12,5%.

And you, how much could you save ?

What if you could save one million dollars?

Just above, we’ve shown how much material can be saved with truly efficient nesting. But how much is that? Now let’s see how much money can be saved.

For this second example, we have ask one of our expert in shipyard. will take the example of the construction of a cruise ship, a mid-sized one, not the largest ones.

Our assumptions and calculation

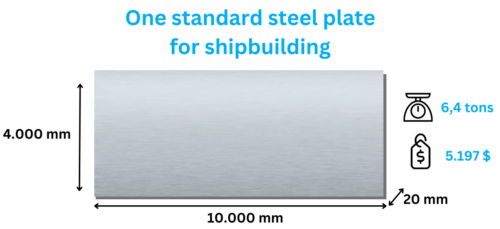

1 steel plate for shipbuilding

- 10.000 mm x 4.000 mm x 20 mm = 6.4 tons

- Steel price: 812 $ per ton (as of May 2024)

- 1 metal plate= 6.4 ton x 812$ = 5.197 $/plate

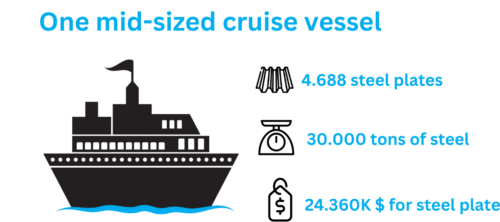

1 medium cruise vessel

- 300.000 steel parts (for reference, the vessel “Wonder of the sea” built by the Chantiers de l’Atlantique contains 400.000 steel parts )

- = 30.000 tons of steel

- Number of sheets needed : 30.000 : 6,4 = 4 688 sheets

- Cost : 24.360.000 $ of steel materials

Money savings with Efficient Nesting

Above, we have seen that a good nesting can reach 12,5 % of raw savings. Let’s even imagine nesting with savings of just 4%. You’ll see the budget savings we can achieve.

The amount of metal roofs for a cruise vessel is 24.360.000$, with a 4% savings = 974.000 $

To be short and clear, with a good nesting CAM software, a project of cruise vessel can save 1 million dollars.

How much is a 4% material saving for you per year?

Material Savings are Greener

Reduction in Material Waste

As we have seen, one of the primary advantages of nesting is the significant reduction in material waste. By employing advanced nesting software, shipyards can meticulously plan the placement of each component cut from these plates, ensuring minimal leftover material.

In the vast majority of cases in the shipyard sector, work is carried out by “block”. With Almacam, it is possible to optimize the nesting of parts from different blocks. This is particularly interesting for certain thicknesses, where the number of parts to be produced in a block is limited, which further reduces material losses. What’s more, with Almacam, offcuts are reusable and will be optimized in the same way as a whole sheet would have been. No nesting loss on off-cuts.

Sustainability and Environmental Benefits

Nesting also supports sustainability efforts within the maritime industry. By minimizing waste, shipyards reduce the amount of scrap metal, which in turn lowers the environmental impact. Additionally, efficient nesting practices can reduce energy consumption associated with cutting and processing materials, contributing to the industry’s sustainability goals. Reducing waste by thousands of steels not only saves costs but also decreases the environmental burden of producing new steel, which involves substantial energy consumption and CO2 emissions .

Efficient nesting helps conserve natural resources by making optimal use of raw materials. This is particularly important as the steel industry is one of the largest sources of industrial greenhouse gas emissions. By reducing the need for additional steel production, shipyards can significantly lower their carbon footprint, contributing to global efforts to combat climate change.