The new version of Almacam v4.0.2 is out providing advanced security & optimized performances

Published on 05 March 2024

Coming with about 50 new features, the new release of Almacam software suite is the result of a half-year of research and development. It makes the process of nesting, cutting and the whole workflow of sheet metal and tube cutting FASTER and SAFER.

Rosalinda Ferrandes, Product Head of Almacam, explains: “Our mission is to help machine builders and metal workers optimize their CAD-CAM production workflow. With this new version, we focused on enhancing the speed and efficiency of users’ day-to-day tasks and make easier for them to secure their environments. As usual, the priorities for this new version are based on our regular discussions with our partners and customers.”

Strengthened security for continuous uptime machines

Managing risk in the era of Industry 4.0 and connected production is not an option. To ensure continuous production and data privacy, this new version strengthens the overall security of Almacam instances.

Among all, metal manufacturers will be able to leverage higher user access controls, enhancements on PostgreSQL database security and robust authentication. This ensures compliance with the security standards of sensitive sites making them even safer. Thus, Almacam helps safeguard manufacturing data and ensures uninterrupted production operations by maintaining the integrity and availability of critical data.

Performance improvements for an even faster software

Almacam 4.0.2 significantly improves the overall software performance for a better user experience and a more efficient CAD-CAM workflow. Processing times have been reduced by 50% or even more for some cases. Some examples:

- In Almaquote, the quote edition is 2,75 faster ! “When you have dozens of RFQs to answer a day, relying on a fast and responsive software is a great help.” explains a metal sales representative.

- Want to generate a workshop document? Speed improved by 25%.

- Time for tube recognition have been cut in half!

These figures don’t sound to you? Sure, you’ll see how your everyday work is nice when you get a tool as responsive as you are!

3D CAM -Tube: new advanced capabilities

Almacam Tube is one of the most cutting-edge modules of the Almacam software suite. Already offering many automation capabilities, optimized nesting and flexibility, the new version comes with new advanced features.

To name just a few new features:

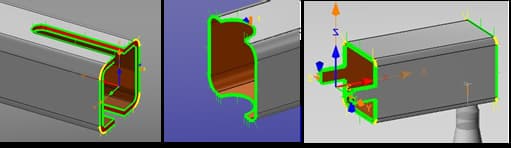

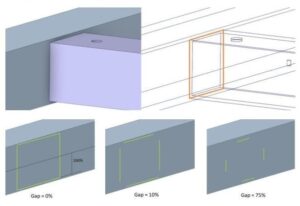

Additional automatic junctions

Not only Almacam Tube enables to configure automatic junctions on holes and extremities with a chop-off, but now it is possible to configure automatic junctions on fold cuts and on extremities corresponding to complex profiles as grooves or notches.

Marking edge intersections between tubes

Marking-type connections can now be added to two T-type tubes in an assembly. This type of connection adds a marker that indicates the tube intersection, without modifying the tube geometry.

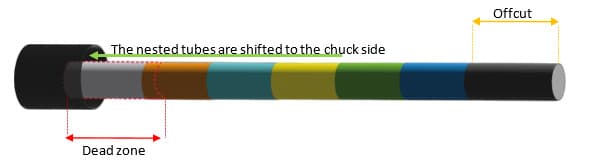

New option for improved offcut management

With a constant focus on reducing material waste, Almacam 4.0.2 delivers a new tube option called Avoid final scrap (AFS) : it makes possible to nest tubes in the dead zone, and shifts the offcut to the opposite side to the chuck.

How to leverage this new version?

Almacam 4.0.2 version if available for all customers with an active maintenance. To learn more about the new features of this release or request help for upgrade, contact us, we’re here for you.