Pilot all your sheet metal cutting machines with the most efficient automatic nesting software

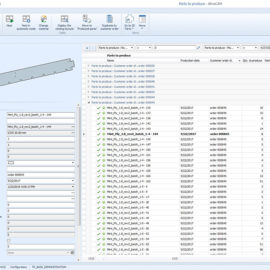

With Almacam Cut, drive all your 2D cutting machines (laser, plasma, oxygen cutting, water jet) and accelerates programming stages, from part preparation to NC code generation. Combining the most advanced nesting algorithms along with automation, Almacam Cut minimizes material waste and increases your workshop efficiency.

“Orders that previously required manual nesting by an operator during their working hours now take up only about one-third of their time. With Almacam, we have achieved an estimated 50% time savings across all our plants. It has become the standard nesting solution for our entire group.”

Andreas Pree, Manager Manufacturing Strategy – PALFINGER

Advanced 2D CAD/CAM tools for designing, nesting and generating cutting programs

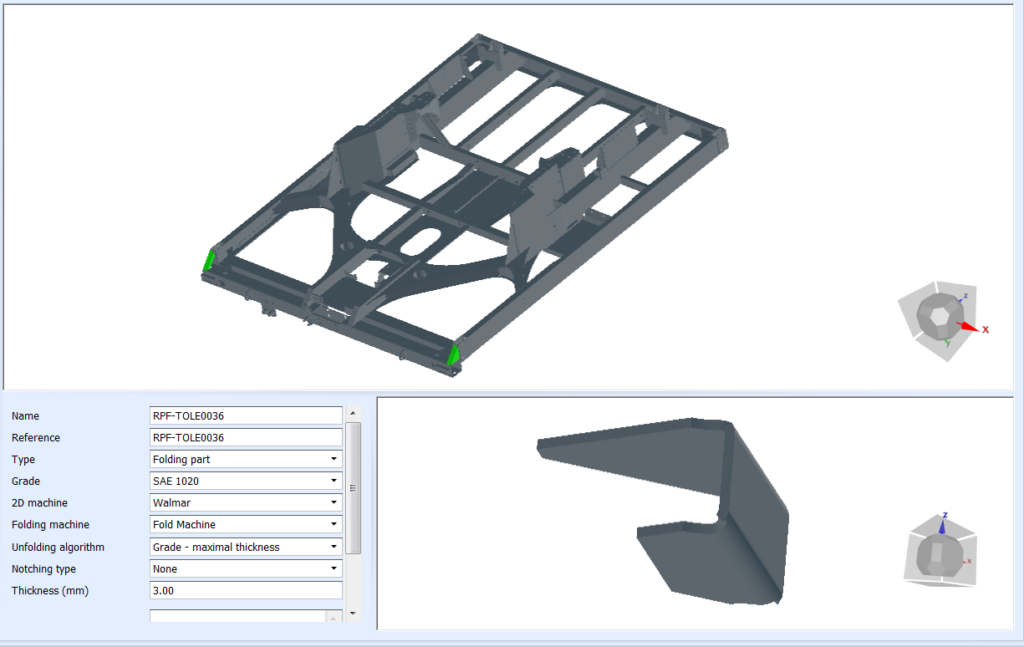

Part design and assembly import

- Design sheet metal parts with the 2D CAD module

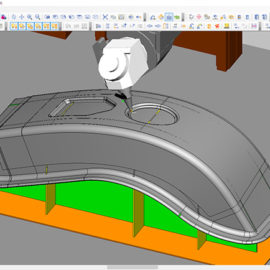

- Import 3D parts from popular formats like STEP, IGES, and native CAD files

- Automatically unfold 3D parts, with options to modify the geometry as needed

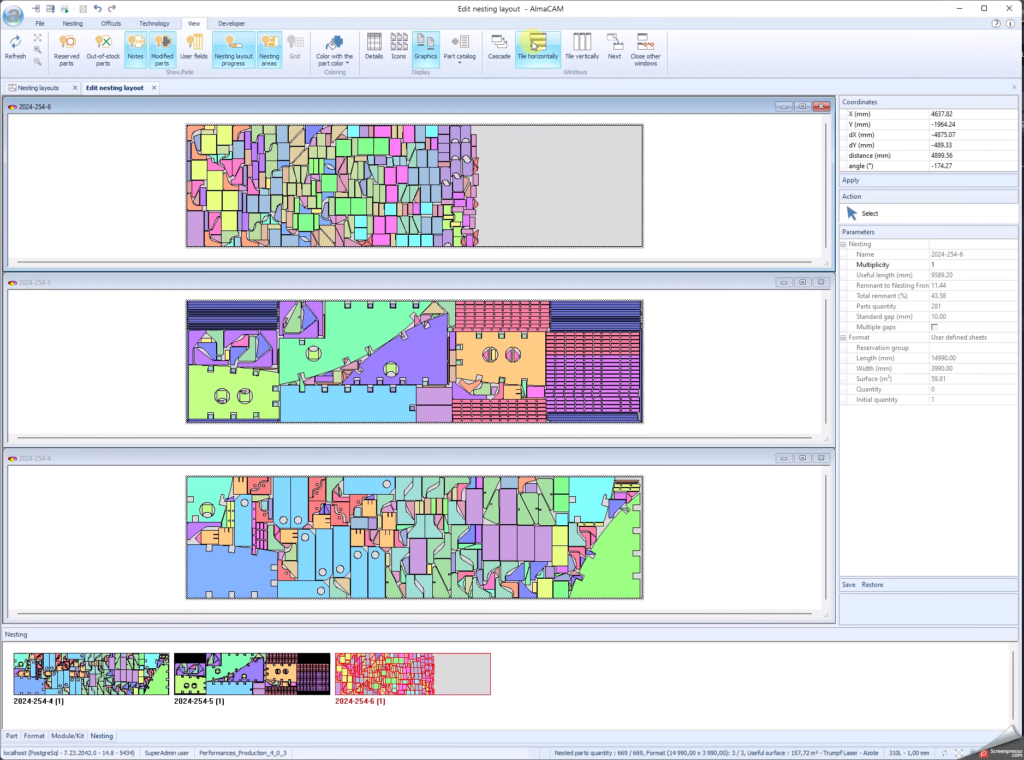

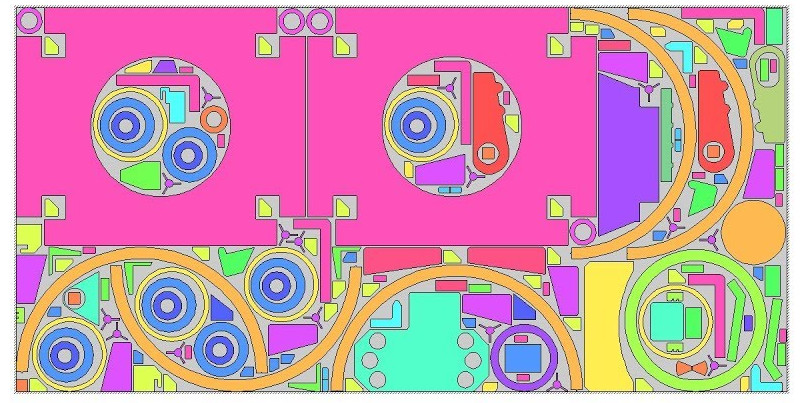

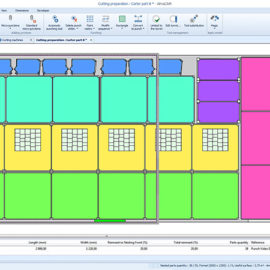

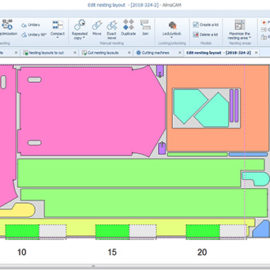

Optimized Nesting for maximum efficiency

For over 45 years, Alma has been a leader in developing advanced nesting algorithms, ensuring customers get the most optimized sheet metal part layouts available on the market.

- High-performance automatic nesting with multiple strategies for efficiency and speed

- Nesting in offcuts

- Optimized nesting in common cuts

- Multi-head nesting

- Easily adjusted part and sheet gaps for specific needs

- Reusable optimized nesting and sub-nesting layouts

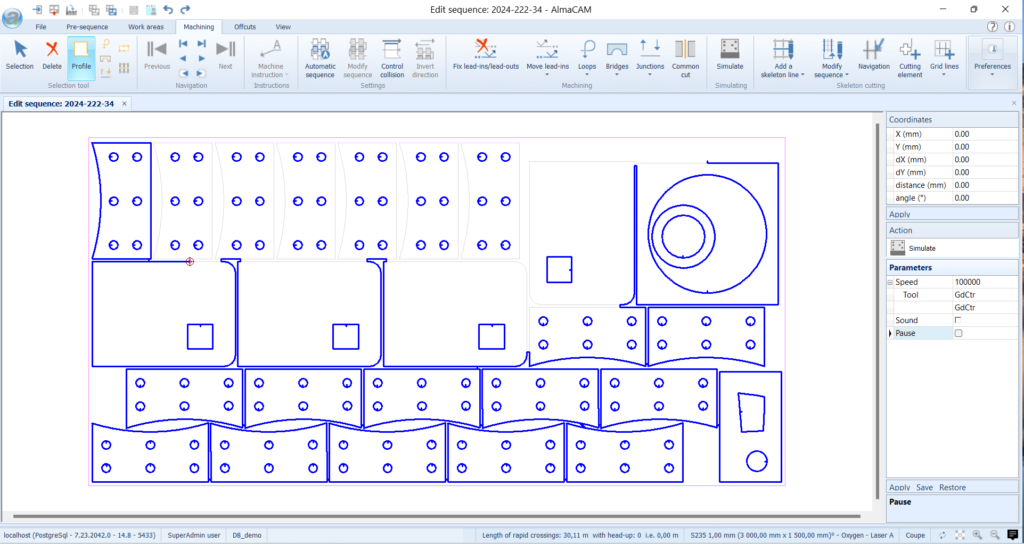

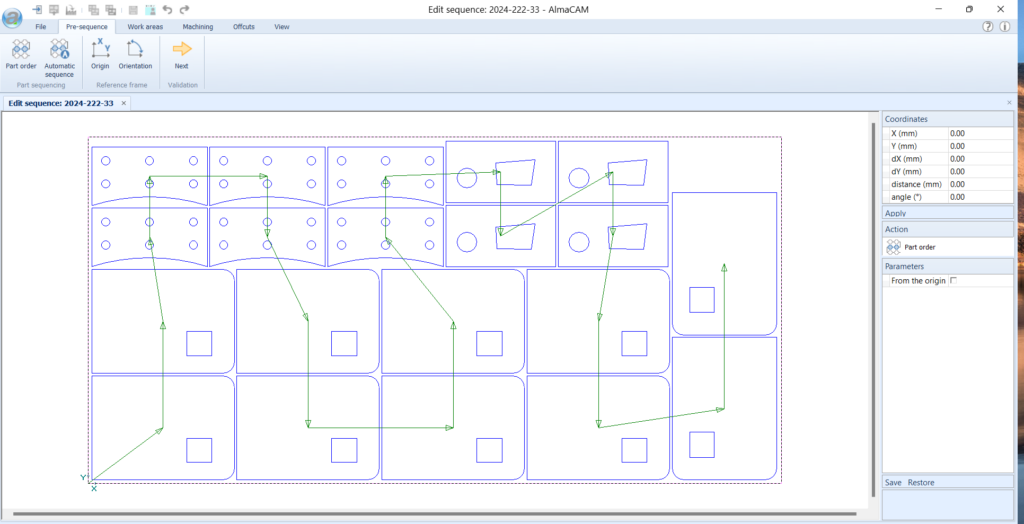

Automated cutting preparation

- Automatic assignment of cutting features, such as lead-ins/outs

- Ad hoc assignment of cutting conditions based on material, thickness, gas…

- Automatic computation of tool paths, even for parts in common cut.

- Efficient prevention against the risk of collision

- Automatic management of skeleton cutting

- Use of several methods to reduce the number of piercings (e.g. bridges, chain cutting, common cut)

- Automatic speed reduction management in corners

- Ability to program beveling heads

Support all brands of 2D cutting machines

Almacam Cut is able to program all types and brands of 2D cutting machines (plasma, laser, oxy-cutting, waterjet), as well as all related processes (cutting conditions, piercing, engraving, tack welding, micro-welds, etc.).

Some 2D cutting machine brands we drive

Perpetual License or Subscription, you choose

Almacam Cut is installed on-premise with a perpetual license or under a flexible subscription with Almacam Pass.