When software makes the difference

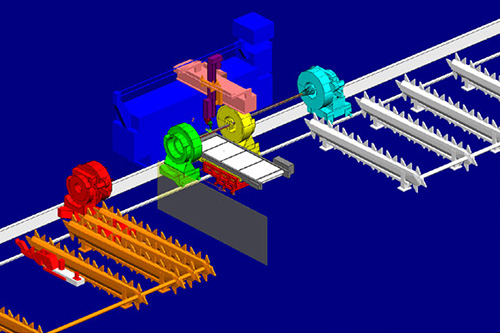

Tube Tech Machinery (now TTM Laser) is an Italian company which specializes in the design and production of equipment destined to the 3D laser cutting of tubes and sheet metal of large dimensions.

The company, based in Cazzago San Martino in northern Italy, was created with the objective of introducing a new and technologically innovative product capable of resolving the complex problems facing this sector where there is a growing need for a completely automated machine capable of combining ease of use and high levels of productivity.

With the software applications from the act/ range, Alma is able to cover every need of the machines produced by TTM. From managing production, with the act/manager for example, and the programming of FL systems for the five-axis cutting of tubes and bars thanks to the act/tubes solution. Or systems for working with sheets for cutting and welding applications and 3D cutting of tridimensional parts with the act/cut solution.

The importance of the “software” component

Too often when we speak about laser cutting machines or their application we forget the software that runs and manages them. We concentrate on more obvious topics like cutting performance, power of the configuration of the system or even the plant itself when we find ourselves in front of an automated line. It is, in fact, taken for granted that the set up is run by a numerical control system but not so common to think about the software that manages the system.

So we tend to deal with just the specific functions that are developed to best integrate the machine into the production context. We also respond to the particular cutting requirements which more and more often represent the real criteria for the choice of the system.

The tried and true partnership between Alma, a leader in the production of CAD/CAM software for working with sheet metal, tubes and bars, and Tube Tech Machinery (TTM) an absolute star in the world of 3D laser cutting, offers us the opportunity to speak about these aspects of the business. Alma’s flexibility in adapting its own software to machines according to the specific needs and problems of Brescia based TTM’s clients demonstrates, in fact, the strategic importance of software components in guaranteeing the levels of excellence demanded by production. The machinery in use, no matter how technologically innovative, can turn out to be unproductive or perform poorly if managed with inadequate software.

Reciprocal synergy

Lets proceed systematically and start by saying that both these leaders are international players and their collaboration generates reciprocal advantagesand stimulates a beneficial cycle orientated towards continuous innovation.

For TTM, in fact, having a partner like Alma which follows and develops its own software, just in time according to the specific problems which result in each case, is a real strong point. This allows TTM to expand its market opportunities and sell itself as a provider of solutions made up of innovative machines run at their best by software which can be customized if necessary.

At the same time, Alma’s collaboration with TTM constitutes important added value because it constantly supplies new stimuli for the perfecting of innovative tools which further increase the functions available with act/ environmental modules, above all, as far as the three dimensional cutting of tubes and bars is concerned.

The “light replication”

With the software applications from the act/ range, Alma is able to cover every need of the machines produced by TTM.

From managing production, with the act/manager for example, and the programming of FL systems for the five-axis cutting of tubes and bars thanks to modules like act/tubes and act/cut 3d. Or systems for working with sheets for cutting and welding applications and 3D cutting of tridimensional parts with the act/cut Professional module.

In this way, the customizing for TTM deals with every level of management of the machines starting with design, for which Alma has developed a powerful instrument called the “light replication” which allows you to reduce calculation times and the quantity of data to be processed when dealing with profiles to be repeated on the same piece. In act/tubes, (the parametric CAD 3D utilized to model tubes and profiles) the production processes are obtained, in fact, by intersecting the main tube with variable section secondary tubes which can be duplicated and replicated in a linear, matrix or helicoidal way. The concept of the “light replication” introduced for TTM allows the establishment of a sequence of master profiles which are then replicated as slaves only in the post processor phase. This postpones the effective duplication of the information for the intersecting tubes and notably reduces the volume of data to be processed which, both in terms of volume and ‘weight’, constituted a significant problem for a Russian company active in the production of tubular structures for petroleum plants. We are talking about tubes which are about 8 meters long which are fitted with 1,200 holes of different geometries, using the FL250 system. This allows the filtration of crude oil. This is an extreme application but it best exemplifies the concept of customizing as applied by Alma.

Alma’s flexibility in adapting its own software to machines according to the specific needs and problems of Brescia based TTM’s clients demonstrates, in fact, the strategic importance of software components in guaranteeing the levels of excellence demanded by production.

The dedicated interface

One aspect which fully confirms the flexibility of Alma’s act/ environment is its total openness towards other CAD systems. This takes place via the standard Pipe/Import interface or with the creation of specifically studied interfaces. Pipe /Import allows the importing of files in the most common formats (Iges, Step, etc.). These geometry files are imported in batch mode and it is possible to add new intersections or enlarge those already in the act/tubes module.

This customizing for TTM has gone even further. In fact, for a producer of high pressure tubes and manifolds a special interface was developed to permit dialog with the Tribon 3m Pipe Modeler. This is the CAD 3d system used by the company to program all the machines installed in the workshop for the production of piping. As well as this, the CAD Tribon is connected to the production management system which isinterfaced with act/manager in order to perfectly integrate the laser machine.

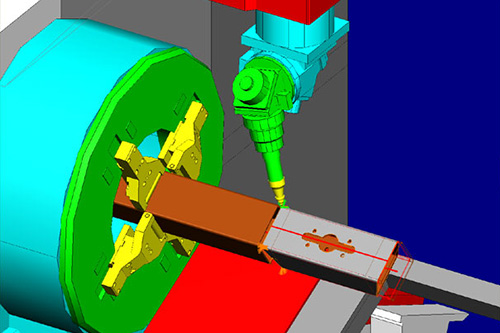

The interface developed in this way allows act/tubes to be used with the information exported from Tribon to reconstruct the designs for tubes necessary for nesting. act/cut 3d, automatically converts all the information, particularly the ones necessary for bevel cutting and the stoppers design. Given that we are dealing with high pressure manifolds, the intersections must be welded to full penetration with particular criteria which necessitates beveled inlets and the stoppers already mentioned which maintain the precise distance necessary for the correct filling of the welds.

With the software applications from the act/ range, Alma is able to cover every need of the machines produced by TTM.

The Resource Editor

Talking about customizing, Alma’s philosophy offers its clients the possibility of creating a resource editor. This is a database which can be customized with all the technological instructions which are imposed for each machine tool. The principal parameters for TTM machines are defined, for example, according to work processes, tools, materials, the quality of the materials and the thicknesses to be processed. Parameters like the piercing times, speed, power, nozzle distance, cycles, gas pressure and frequency are defined according to the work processes and the tools which are automatically applied to cutting profiles according to their dimensions.

The materials and the tubes/profiles are managed, in part, from the data base which is common to all of the machines. Here, the client can insert the cross sections of commonly used tubes and codify them. For TTM, data base has also been inserted with profiles of the open type, IPE or C cross beams. More expert users can create their own macro designs or ask for them to be developed. In particular, for certain clients, rectangular and slotted perforations with micro-junctions and V cuts for bending rectangular tubes have been created.

Creation and simulation of the program

The functions of act/cut 3d have also been customized to allow the designing and creation of optimum programs for TTM machines. In fact, special instructions have been tailor made for the FL600, FL400, FL250 and FL200 systems. These calculate an automatic solution while leaving the user the possibility of interactively modifying the program obtained later.

The work process is connected to the piece and consists in marking and cutting operations as well as the cutting of the holes and the extremities of tubes in one or more passes including information for movement and torch inclination. The passes are defined from a list of control points which specify the geometrical information (offset, orientation and tolerances) and the processes (tools, speed, ON/OFF sensors etc.) The scheduling phase determines the order for the carrying out of the passages.

In the work process, one passage determines the laser path or the marking head with reference to the piece being processed.

There are many solutions possible for the same path based on the type and complexity of the machine (rotate the tube or not, shift the tube or not, position the head to the right or the left, the number of mandrels used, unload onto transport or conveyor belt, etc.) For the FL600 and FL400 machines with multiple mandrels, for example, the program for a piece can be different according to its position in the nesting and what you find at the beginning, half way along and at the end of the tube. The software automatically recognizes the external or internal side of the tube or the thickness and so classifies the cutting profiles as first cut, last cut and perforations. It then attributes the kerf to the left or the right and determines the sequence for the cut. It also determines the starting point on each profile.

act/cut 3d allows the real simulation of the program by demonstrating the movements of the TTM machines and the tubes being processed. Thanks to this simulation of all the axes and the table for the speed and acceleration data, the software calculates the cycle times necessary and prints a spread sheet in Excel. The post-processor is customized to deal with CNC files for D.Electron Z32 and Siemens Sinumerik 840 numerical control equipment with which TTM laser systems are typically equipped. It is clear, at this point, that customizing is standard operating procedure in Alma. In this way the company confirms its market leadership. It adds the unique capacity to tailor make its software to the clients specific needs with a complete range of CAD/CAM options. Made to measure tailors or software house?

© 2007 Alma