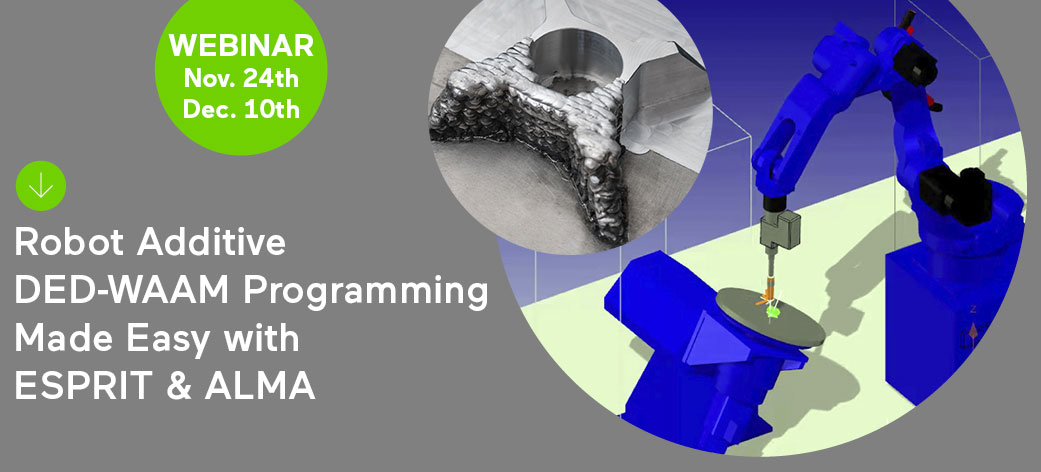

Robot additive DED programming made easy with ESPRIT & ALMA – Webinar on Nov. 24th & Dec. 10th

Published on 12/11/2020

Join our webinar to learn about our CAM solution dedicated to robotized DED-WAAM processes: November 24th at 10:00 a.m. Central European Time and December 10th at 11 a.m. North American Eastern Standard Time.

Additive manufacturing technologies are undergoing rapid development in industry. In the category of DED processes (Direct Energy Deposition), WAAM technology (Wire and Arc Additive Manufacturing) is fusion by electric arc of filler metal in the form of wire. It is installed on a robotized cell and is used to create 3D parts by means of successive welding bead deposits. This technology makes it possible to very quickly manufacture large metal parts at reduced cost, opening up new horizons for additive manufacturing.

Based on this observation and their respective CAD/CAM expertise in programming machining operations and off-line programming of robots, ESPRIT and ALMA partnered to design a single Additive Manufacturing solution dedicated to robotized DED-WAAM processes.

This CAD/CAM solution combines the ESPRIT CAM and ALMACAM WELD software, to manage the entire robot programming process:

- CAD import of the finished 3D part;

- Modeling and simulation of the material deposits;

- Trajectory calculation with obstacle avoidance and generation of the robot programs.

The ESPRIT CAM solution can then be used to finish the part by removing material (subtractive).

This webinar first situates the DED and WAAM technologies in the Additive Manufacturing universe and details their applications and benefits. It will then show the main steps for programming a robot with the ALMA-ESPRIT solution, adaptable to any type of 6-axis welding robot. After the presentation, get personalized answers from Alma and ESPRIT experts during a live Q&A.