While celebrating its 40th anniversary, Alma is resolutely investing in the industry of the future

Published on 30/09/2019

Ever since it was created 40 years ago, Alma has specialized in cutting optimization. Today it is internationally renowned for its technical expertise, which it has developed over the years in many different countries. On the strength of its cooperative human values, Alma is pursuing its industrial strategy based on the development of an extended range for Industry 4.0, a long-term corporate project and the commitment of its employees.

An original business which has made a name for itself as a vendor of industrial software

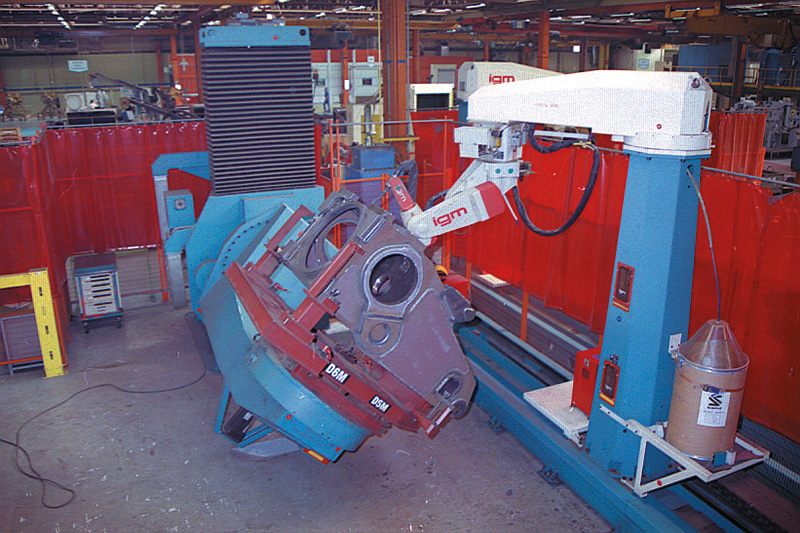

In 1979 researchers in Applied Mathematics from the University of Grenoble designed the first automatic nesting software program. The aim of nesting is to economize on raw materials when cutting textiles or sheet steel. Alma was launched and grew quickly in the sector of software used to control cutting and sheet metal machines, and then robots. Today Alma offers a comprehensive range of CAD/CAM software packages for cutting all kinds of shapes, sheet metal working and machine welding.

Alma is a major player in this market. It has become a strong and prosperous group employing 160 people, generating consolidated net sales of €16.7 million (50% increase over the last 5 years), physically present in 8 countries, and represented in 15 others.

Specializing in optimization and digitization of production

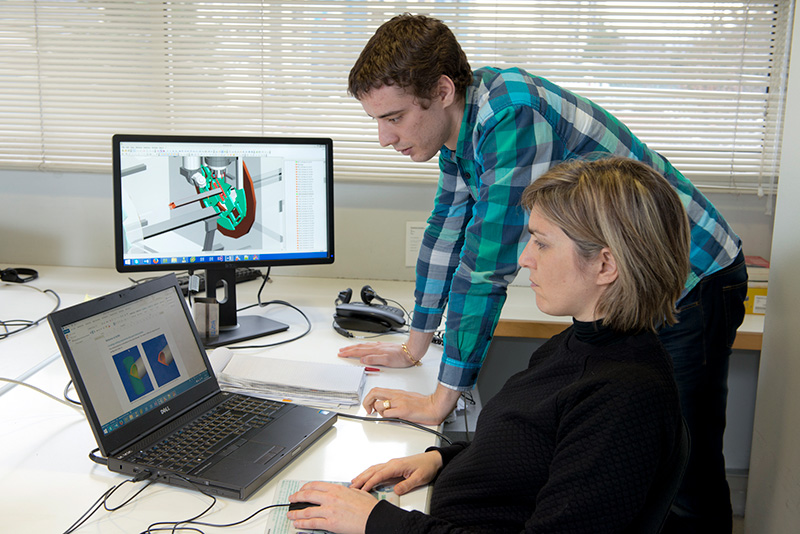

Alma’s growth drivers are technical expertise and innovation. Ever since the company was created, it has designed software solutions to optimize the potential of machines and robots. Alma has always supported the development of emerging technologies, and to do so it works in close collaboration with manufacturers of machine tools and robotized systems.

The CAD/CAM applications in the Almacam range cover every process for cutting metal and soft materials (cutting by fluid jet, punching, milling/routing, 5-axis cutting, robotized cutting, cutting of sections and tubes), folding/unfolding and robotized arc welding. They are completed by a set of modules centered on production management and control (quotes, planning) and integration into the industrial company’s information system. Alma’s software linking CAD, ERP and the workshop meets the challenges of Industry 4.0.

A pioneer in nesting software

From the beginning, Alma’s nesting algorithms have contributed to the performance of its CAD/CAM cutting software. “We are also the only market player that develops and sells our algorithms as software components to other CAM or ERP software vendors” Laurence Ruffin, Alma’s CEO, explains. Thanks to this unrivaled expertise and our 100% proprietary technology, our nesting software products are helping thousands of companies to save on material consumption, in many different sectors, and for all kinds of material. And with the prospects offered by cloud computing and artificial intelligence, we are opening up new horizons in the field of cutting optimization.“

International multi-faceted development

Alma’s growth in its niche sector has been achieved through organic and external growth, as well as international development.

Although Alma has enjoyed steady organic growth since the 1980s it is external growth that has enabled it to extend its product range, broaden its customer base and become stronger on certain markets. With the acquisition of Aleph Technologies in 1996, Alma broadened its range to include robotics (welding, cutting, etc.) and 3D machine programming (cutting of shaped parts, tubes and sections). In 2002 when it took over Sapex, another long-standing vendor, Alma completed its expertise in “fine sheet metal” and became the French market leader in sheet metal CAD/CAM. The same approach was chosen to acquire skills and gain market share in Germany with the takeover in 2018 of Asco Data, a renowned vendor based in Bremen and specialized in automated programming of complex punching and routing machines.

In addition Alma has gradually adapted its organization to a worldwide market and built up a multi-faceted distribution network. The backbone of this network is formed by distribution subsidiaries and joint ventures. In this way Alma has set up businesses in Italy (1991), Germany (1999), China (2007), Brazil (2009), USA (2010), Spain (2016) and Singapore (2017).

“It is very important to be able to adapt to completely different customers on the industrial software market” Laurence Ruffin notes. “Thanks to our products ranging from software components to turn-key software applications, commercialized under the distributor’s brand or our own brand, we have also established numerous partnerships with manufacturers of machine tools and robots, as well as software vendors in fields related to ours. Today ¾ of our software licenses are sold outside France, and Alma is one of the world leaders in its sector.“

A distinctive corporate culture

Alma was created as a cooperative company (SCOP) in 1979, and in France Alma is entirely owned by its employees. The cooperative status of the company has a big influence on Alma’s corporate culture, based on values shared by all the employees: empowerment and accountability, mutual trust and solidarity, sharing of decisions and results, the importance of doing a good job, a special attention paid to the quality of customer relationship, etc.

By placing the emphasis on the corporate project and personal development of employees, and by establishing cooperation as the cornerstone of the company internally and as the basis for relationships with customers and partners, Alma’s corporate culture encourages a spirit of initiative and creativity, promotes the value of technical expertise and gives pride of place to customer satisfaction.

A group looking to the future

Thanks to its different areas of expertise and its position on the market achieved over 40 years, Alma is continuing to implement an ambitious growth strategy in several fields.

Continuing to invest massively in its products and to anticipate the needs of Industry 4.0

Product investment is increasing strongly, and nearly 30% of the payroll for Alma’s CAD/CAM software publishing activity is today devoted to R&D. Several projects are being developed, in the areas of automation, embedding of Almacam software into enterprise information systems, workshop planning and management, data flow processing and robotics.

“Our objective is to go further with Industry 4.0, in particular by means of strategic partnerships, and to propose integrated CAD/CAM-ERP offers as well as MES solutions to retrieve, visualize and exploit machine data“ Laurence Ruffin explains. “In addition, the modularity of our software enables us to extend our range of software components for other software vendors and capitalize on our algorithm expertise.“

Counting on the web

The web represents a huge opportunity for innovation in industry. Alma is working in its fields of expertise (processing of geometric data, cutting optimization, etc.) to develop applications that are even smarter and more automated thanks to machine learning. Nest&Cut is an innovative on-line automatic nesting application launched at the end of 2018 which prefigures a complete suite of Cloud applications. It gives Alma a strong position in the market for SaaS CAM software.

Beyond optimization, Alma would like to offer other web-based services, such as quotes or exploitation of production data. The ambition is to propose hybrid “heavy client/web” solutions to make the most of both environments.

Pursuing international development

Alma’s strategy is necessarily conceived on an international scale, whether it concerns product development in partnership with other structures, deployment of the distribution network or external growth. Alma’s projects also require a strengthening of its presence in mature industrial markets (Germany, United States, etc.) as well as in emerging countries (BRICS, South-East Asia, etc.) and on new market segments in several countries simultaneously, in particular through the SaaS software offering.

Remaining an independent group and preserving its cooperative corporate culture

Alma is strong because of its cooperative status, guaranteeing the independence of the group (it is not possible to sell a SCOP), and its underlying values. It places the priority on the long-term future of the corporate project, rather than short-term gains. As a result, Alma is not involved in offshore business or sub-contracting to low-cost countries. The choice for in-house developed software guarantees territorial anchoring and product quality.

Although it is part of Alma’s development strategy to be large enough to pool resources and invest, this strategy in fact aims at making a difference through technical expertise and by bringing together players who share resources and know-how in a logic of mutual benefits.

This rationale reinforces investment and innovation while facilitating an increase in the workforce. The independence of the Alma group is therefore part and parcel of a coherent industrial strategy, as well as a mindset that is both financial and human.

“This approach combining economic performance, development of individuals and the common good is the basis for the Alma project” Laurence Ruffin sums up. “We are seeking to develop a prosperous, innovative expert company, but also to promote a company where each person is included and where wealth is widely redistributed. At the same time the company’s long-term future is ensured thanks to substantial indivisible reserves (40% of income each year) making relocation impossible and favoring R&D.” This is a high performance business model which has stood the test of time, respectful of people and aiming to contribute to the development of the territories where it is located.